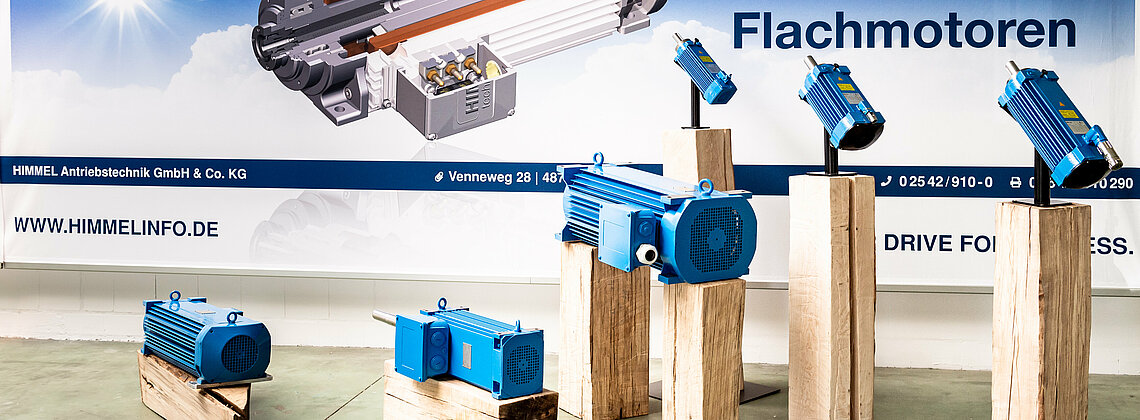

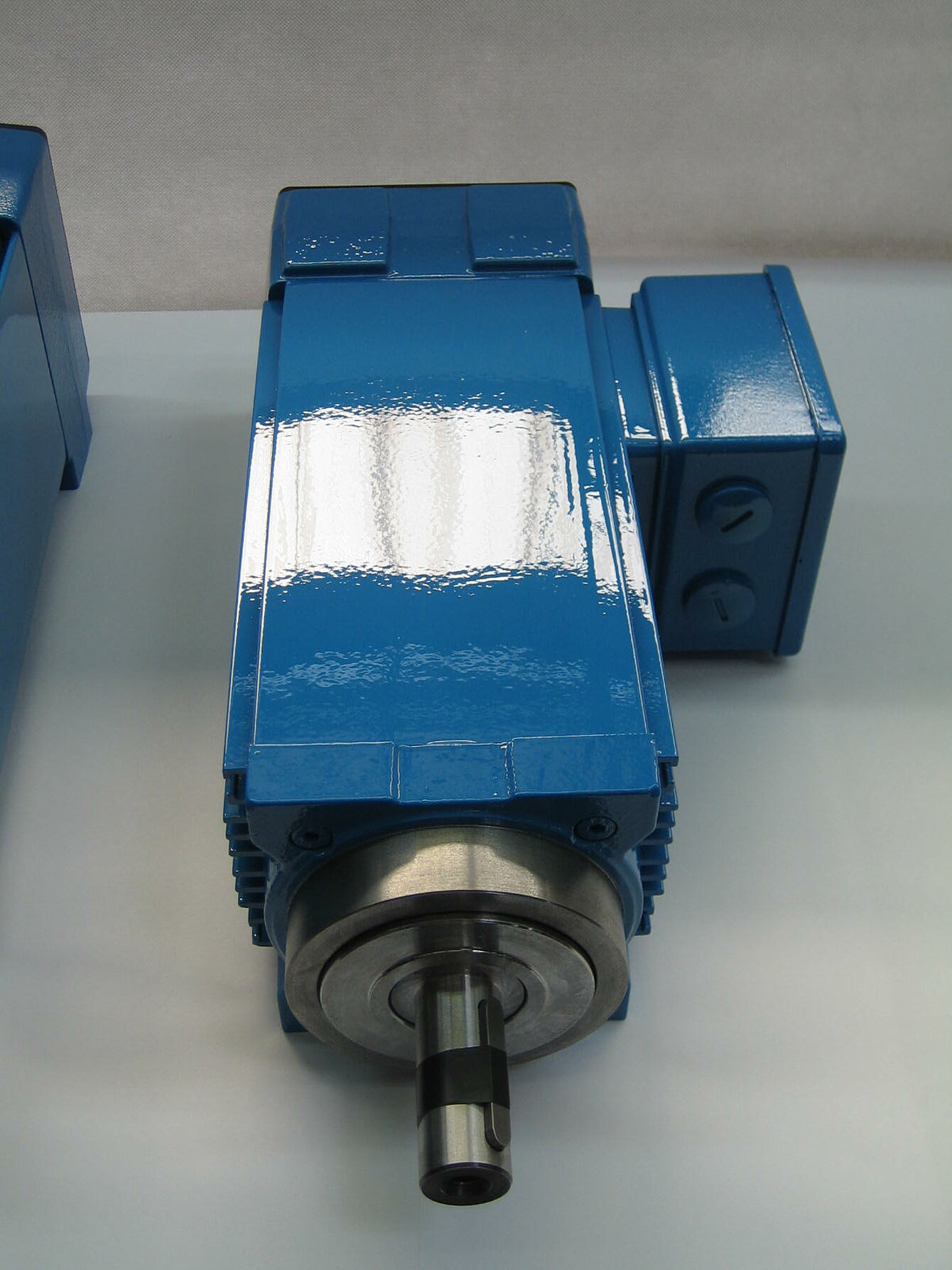

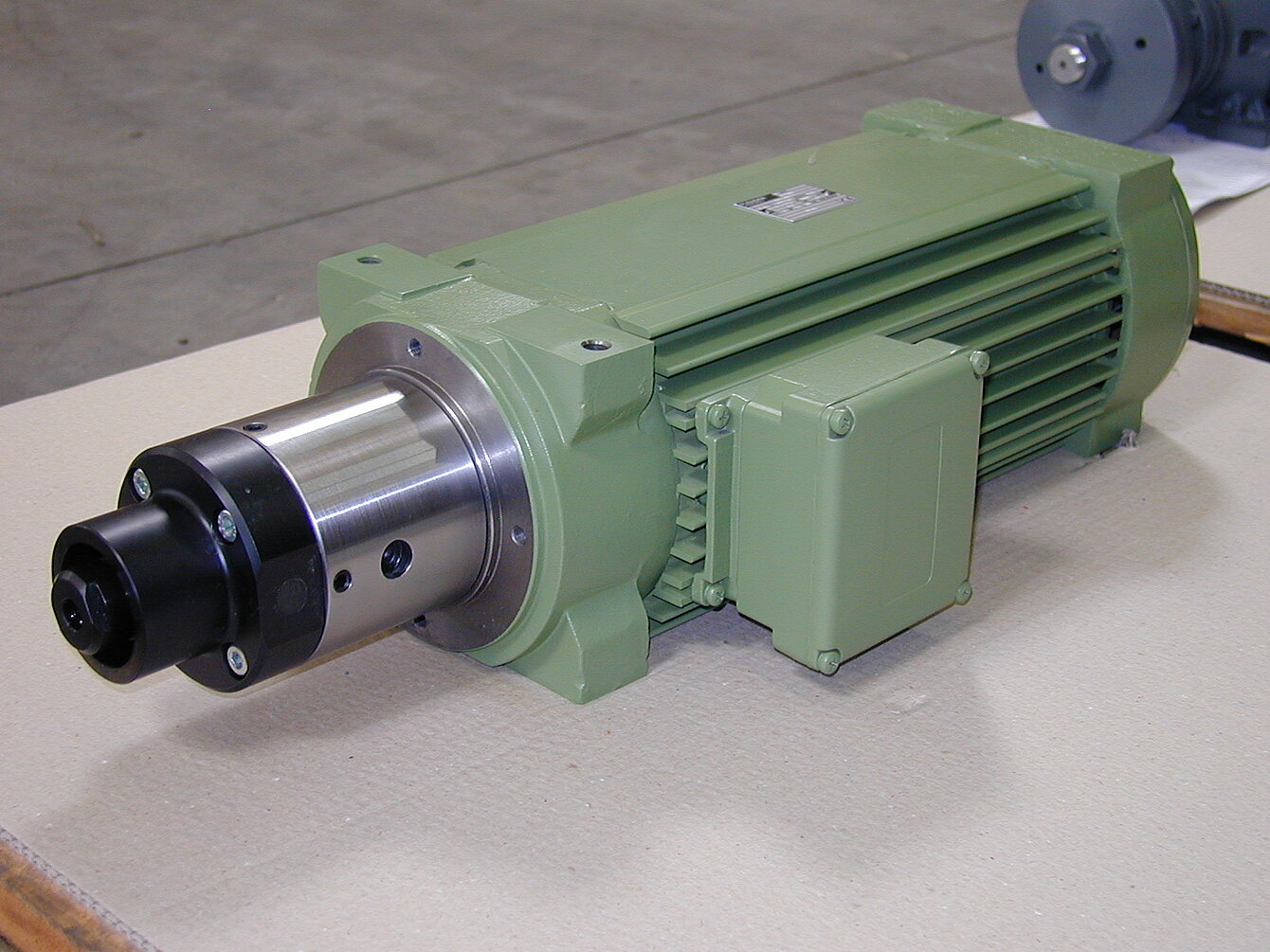

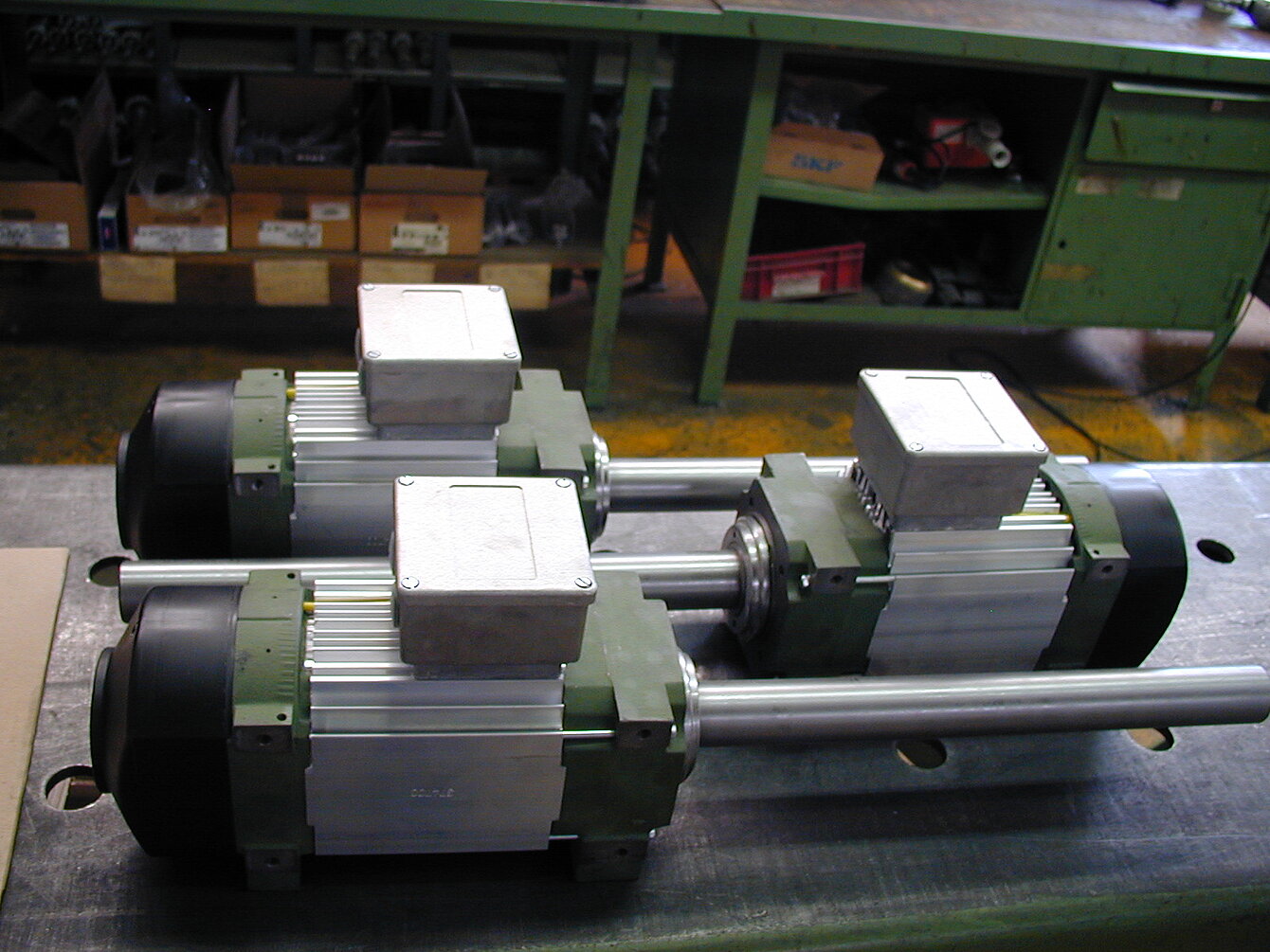

Flat motors

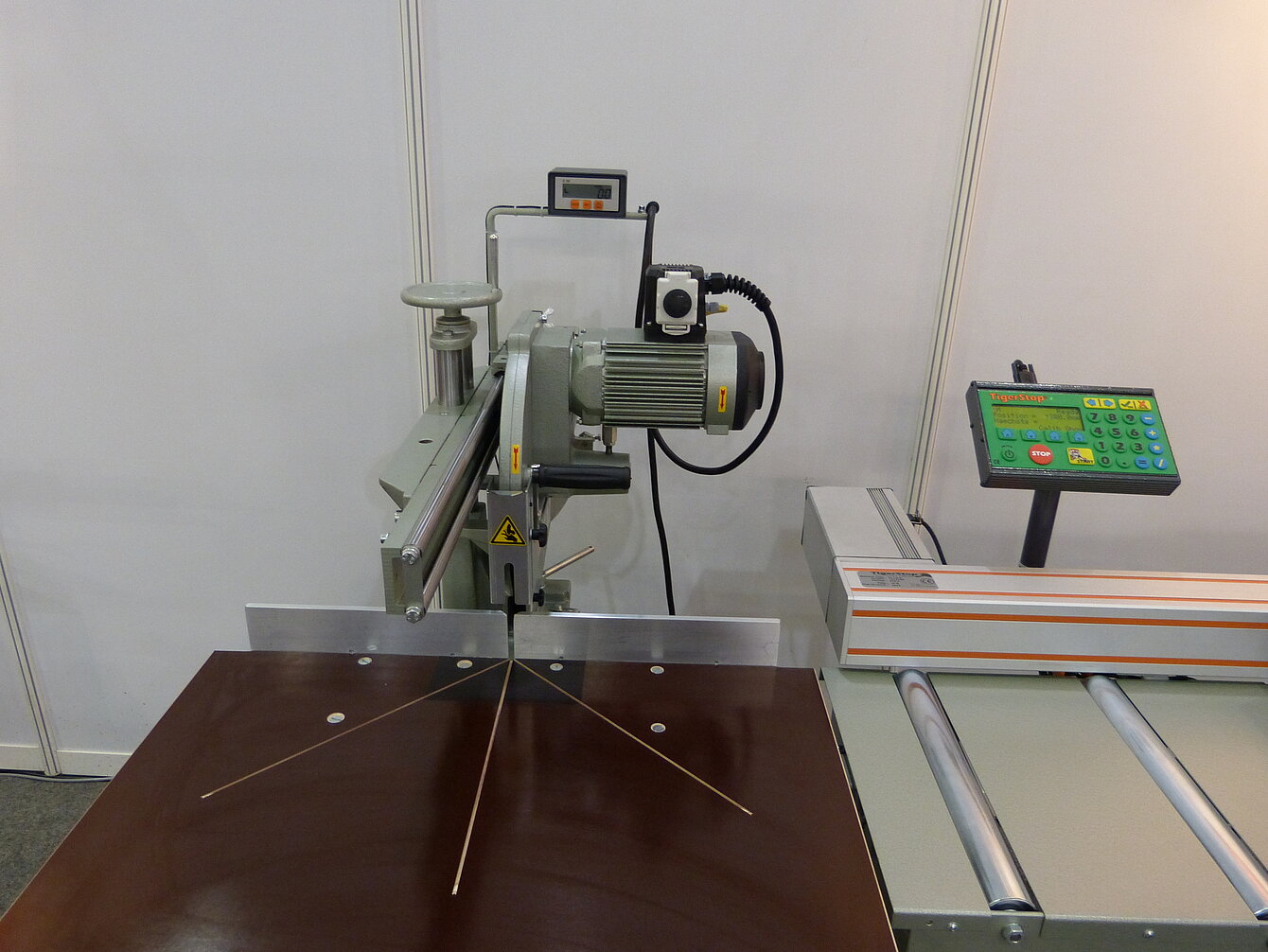

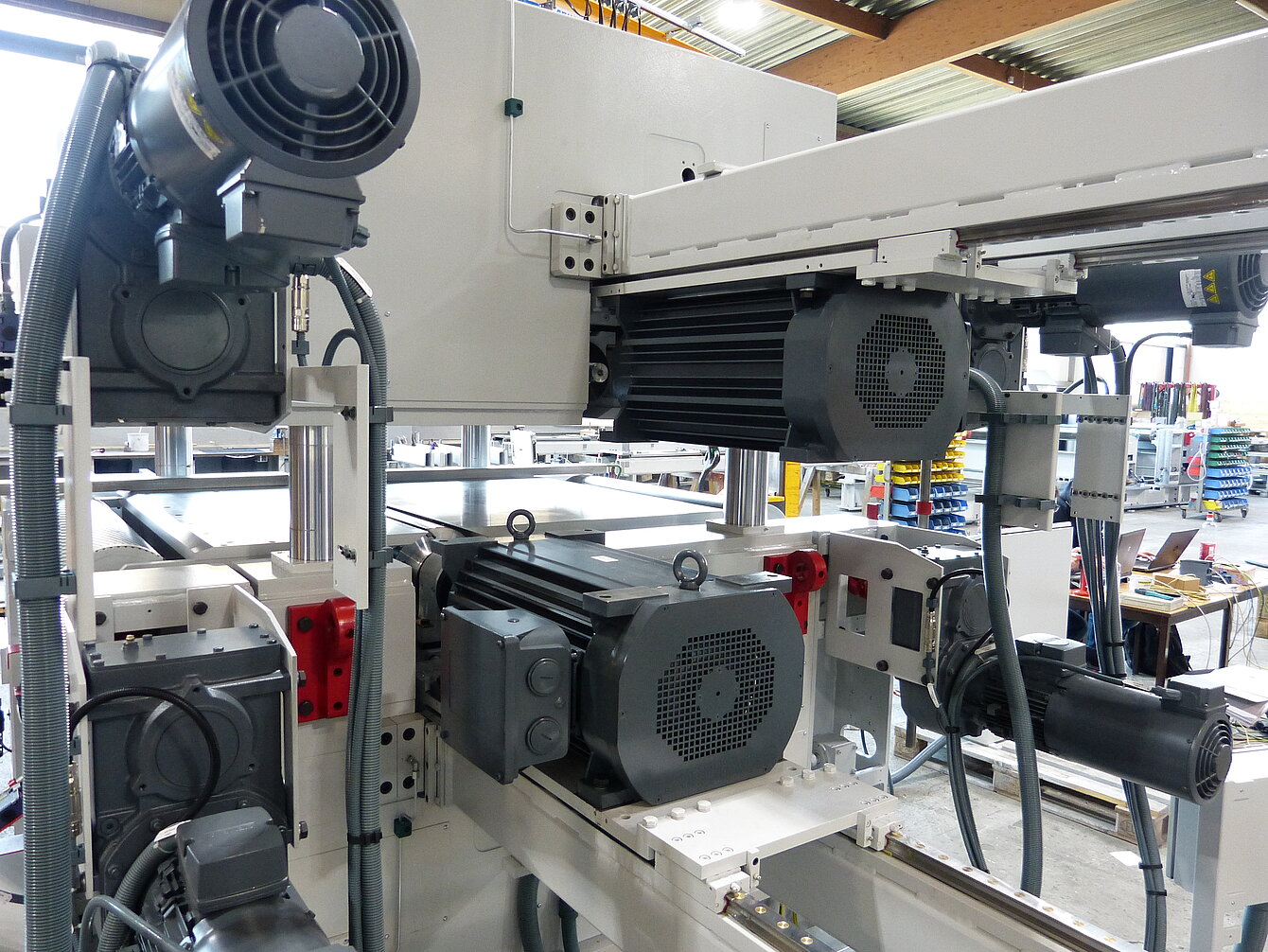

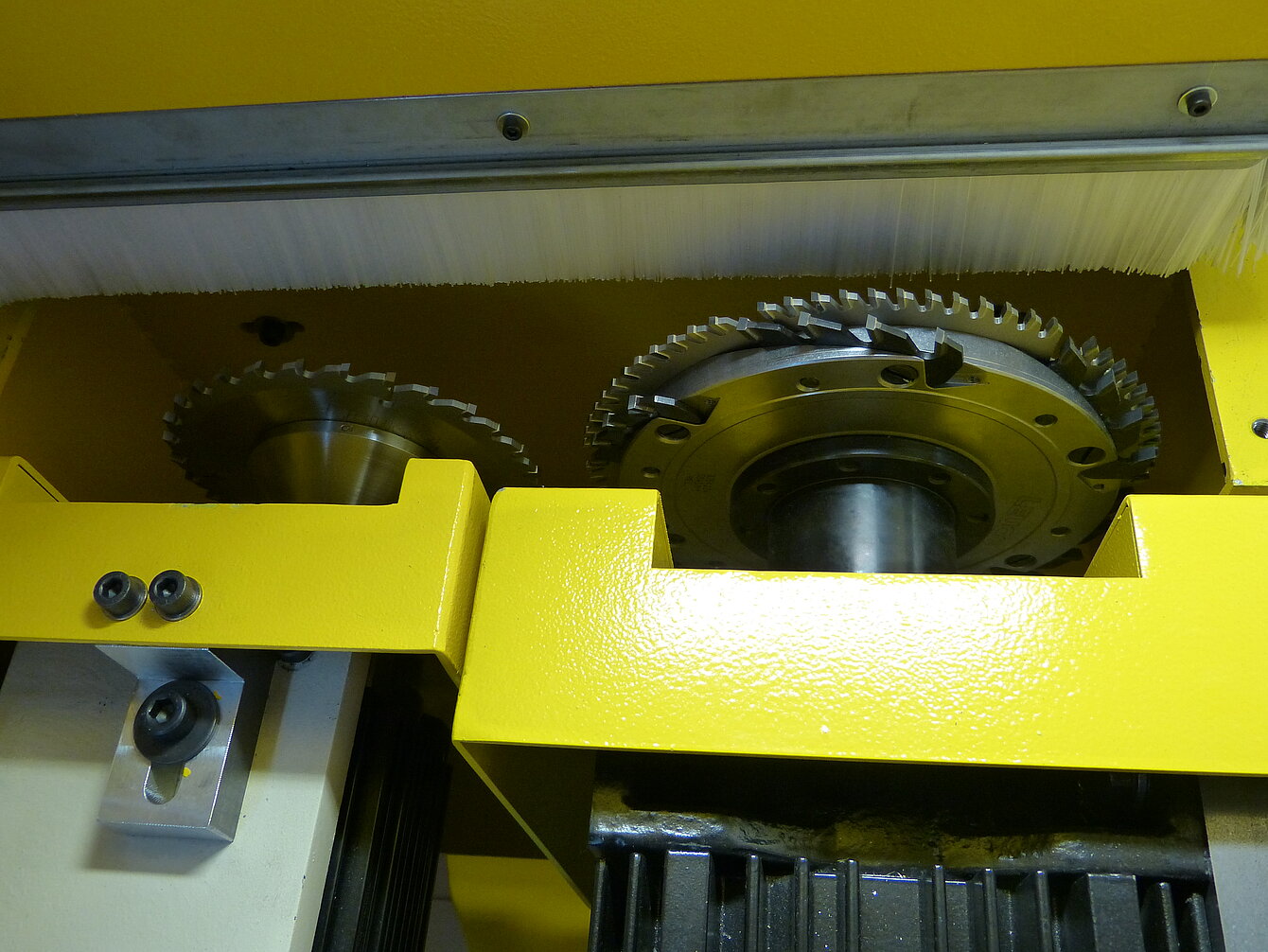

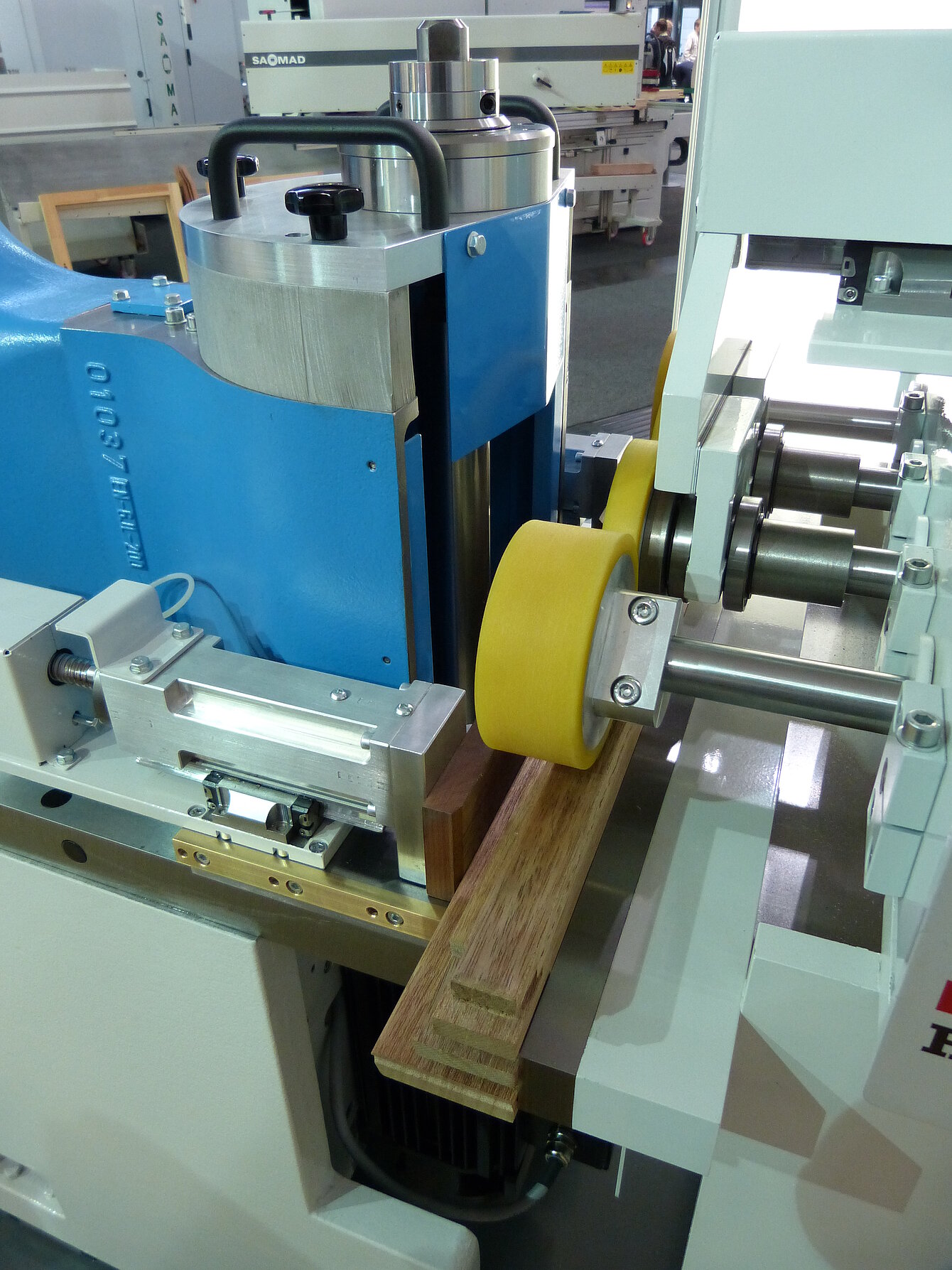

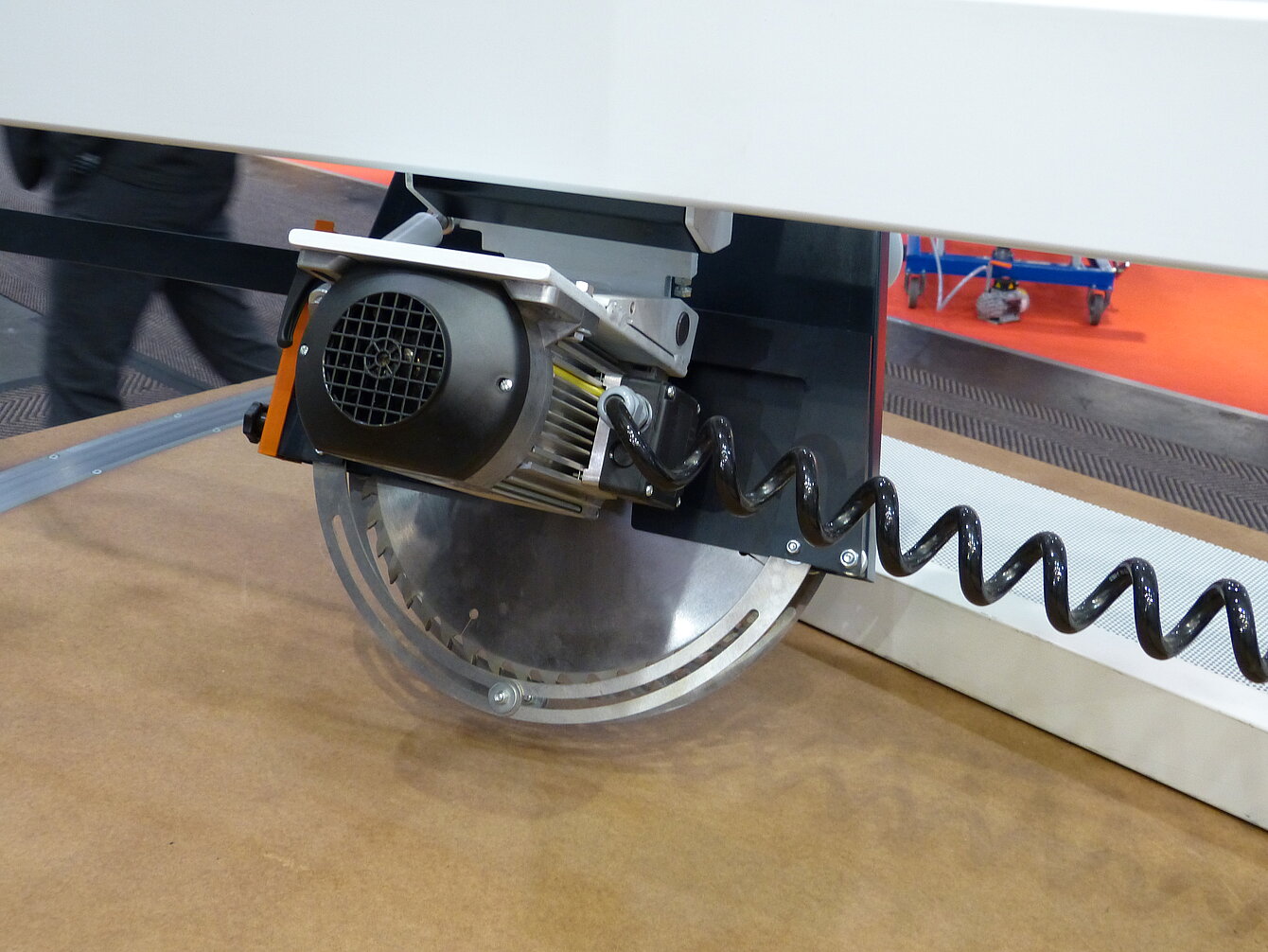

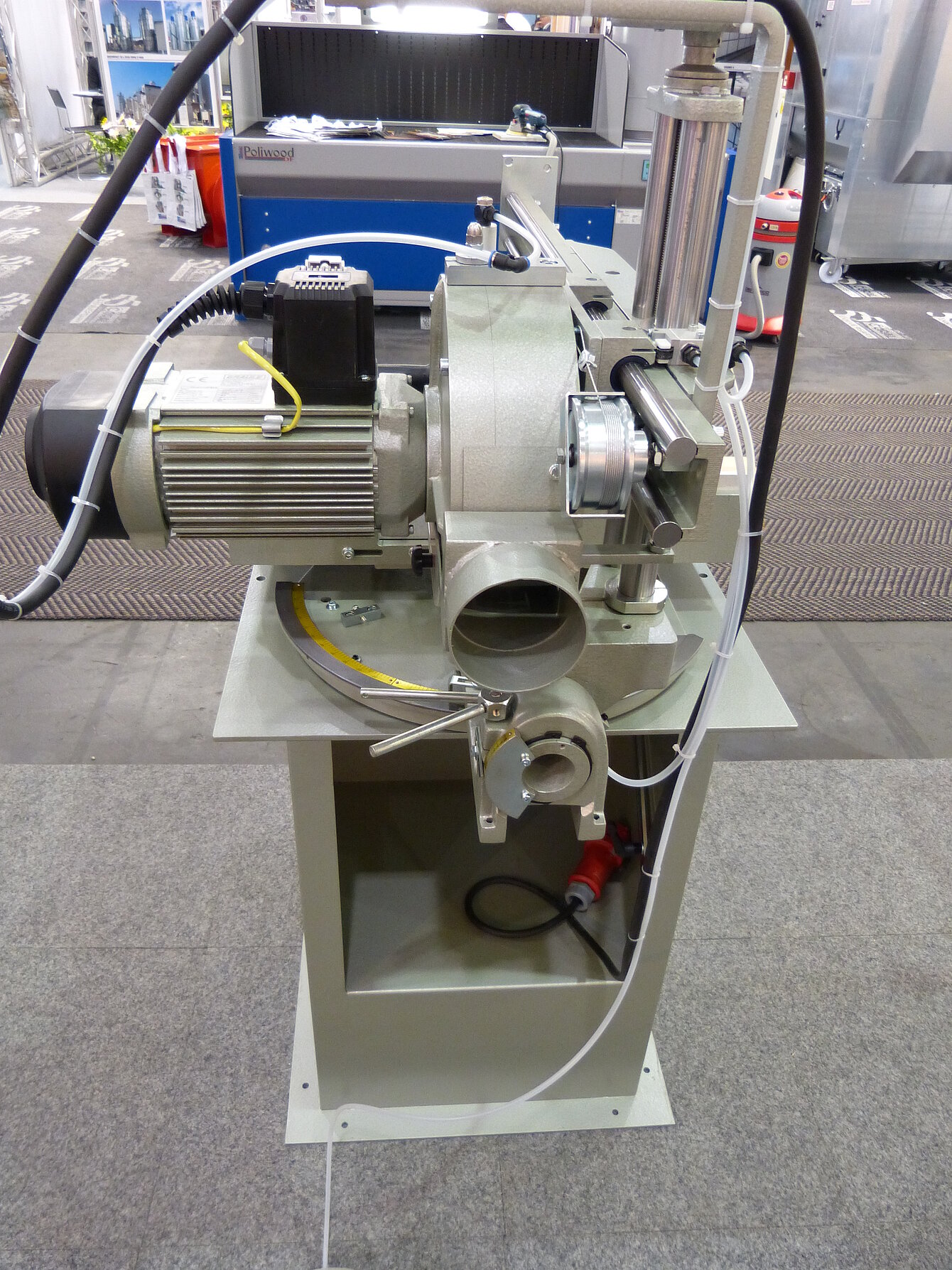

HIMMEL®_ Flat motors have a compact and space-saving design that is ideal for milling, cutting, scoring, boring, sawing, chipping and grinding - in both complex heavy-duty machine systems where demands on the drive unit for operating precision and performance are high, and simple machine systems where an affordable and reliably drive solution is needed.

Our flat motors have been design so that they will operate flawlessly, even under the toughest of conditions.

The HIMMEL®Flat motor range consists of six different design sizes so that we will always have the right motor for the widest range of usage conditions. Alongside our decades of experience, our motors are under constant development. The latest technology and the specific needs of our customers are what define our products.

CONTACTS

Commercial Sales

Stefanie Erning

+49 (0) 2542 910 301

stefanie.erning@himmelinfo.de

Technical Sales

Felix Pollmann

+49 (0) 2542 910 386

Felix.Pollmann@himmelinfo.de

Technical Sales

Rainer Schlüter

+49 (0) 2542 910 208

Rainer.Schlueter@himmelinfo.de

Technical Sales

Dennis Schültingkemper

+49 (0) 2542 910 231

Dennis.Schueltingkemper@himmelinfo.de

Advantages

- Compact and space-saving design

- High running precision and smoothness

- High performance

- Rotational speed from 1000 rpm to 24,000 rpm

Electrical connection options

- Terminal box made from break-resistant plastic or cast aluminium

- Variable location of terminal box

- Cable version

- Plug design for direct connection up to 25 amps

Optional tool mounts

- DIN6388 or DIN 6499 collet chucks

- HSK-C for manual changing

- HSK-F for automatic changing

- HSK-E for automatic changing

- Hydro-clamping system

- Hydro-format system

- Flange disc for attaching saw blades

- Quick-change system for saw blades

- Angular gear with 1:1 transmission

- Further tool mounts based on customer requirements

Applications

- Timber industry

- Furniture industry

- Forestry

- Timber processing

- Aluminium processing

- Plastic processing

- Glass processing

- Stone processing

Features

- IP54 standard protection rating

- Self-cooling using integrated fan

- Suitable for frequency converter operation

- Rotational speed range up to 24,000 rpm

- Power up to 115 kW

Options

- Voltage and frequency selectable

- Electromechanical braking

- Winding protection PTC; PT100 or PTO (WT)

- Terminal box and connectors up to 25 Ampere

- Certification for ATEX Zone 22 (3D) possible

- cCSAUs certification

- Stationary heating

- Speed sensor

- Shaft end with special design according to customer requirements

- Stainless steel shaft

- Reinforced bearings

- Labyrinth seal available on driven and non driven side

- Protection rating up to IP66

- Rotary union for fluids

- Sealing air connection

Technical data

Motor sizes are measured from the lower edge of the food to the centre of the drive shaft (centre height). Where installation spaces are narrow, vertical installation of flat motors is possible.

Model K55

- Power: 0.6 kW to 5 kW

- Speed: 3,000 rpm to 18,000 rpm

Model K62

- Power: 0.5 kW to 12.5 kW

- Speed: 1,500 rpm to 24,000 rpm

Model K75

- Power: 1.6 kW to 24 kW

- Speed: 1,500 rpm to 12,000 rpm

Model K90

- Power: 5.5 kW to 31 kW

- Speed: 1,500 rpm to 9,000 rpm

Model K112

- Power: 5.5 kW to 60 kW

- Speed: 1,000 rpm to 6,000 rpm

Model K160

- Power: 45 kW to 115 kW

- Speed: 3,000 rpm to 6,000 rpm