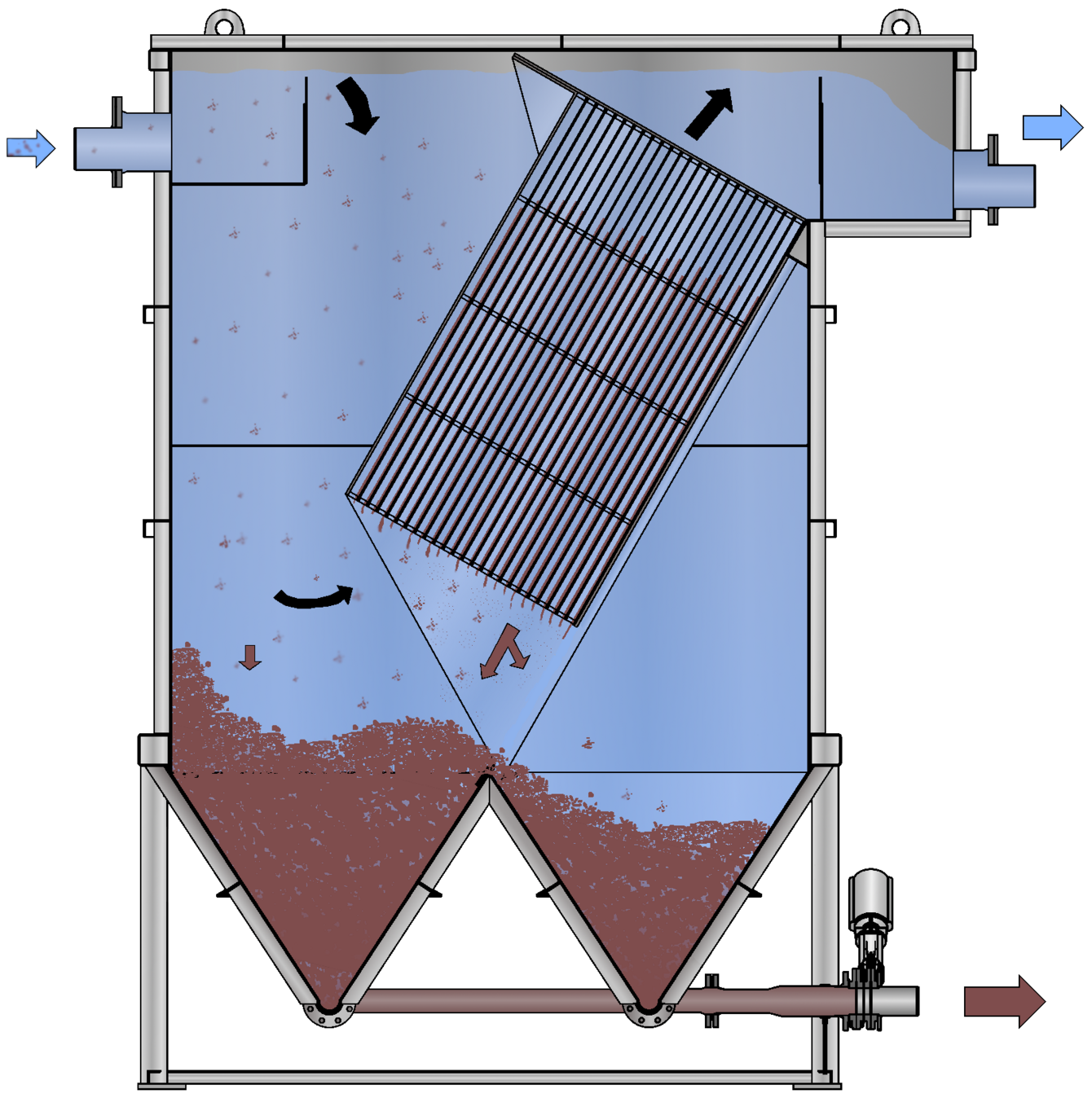

KLÄRFIX® process water treatment

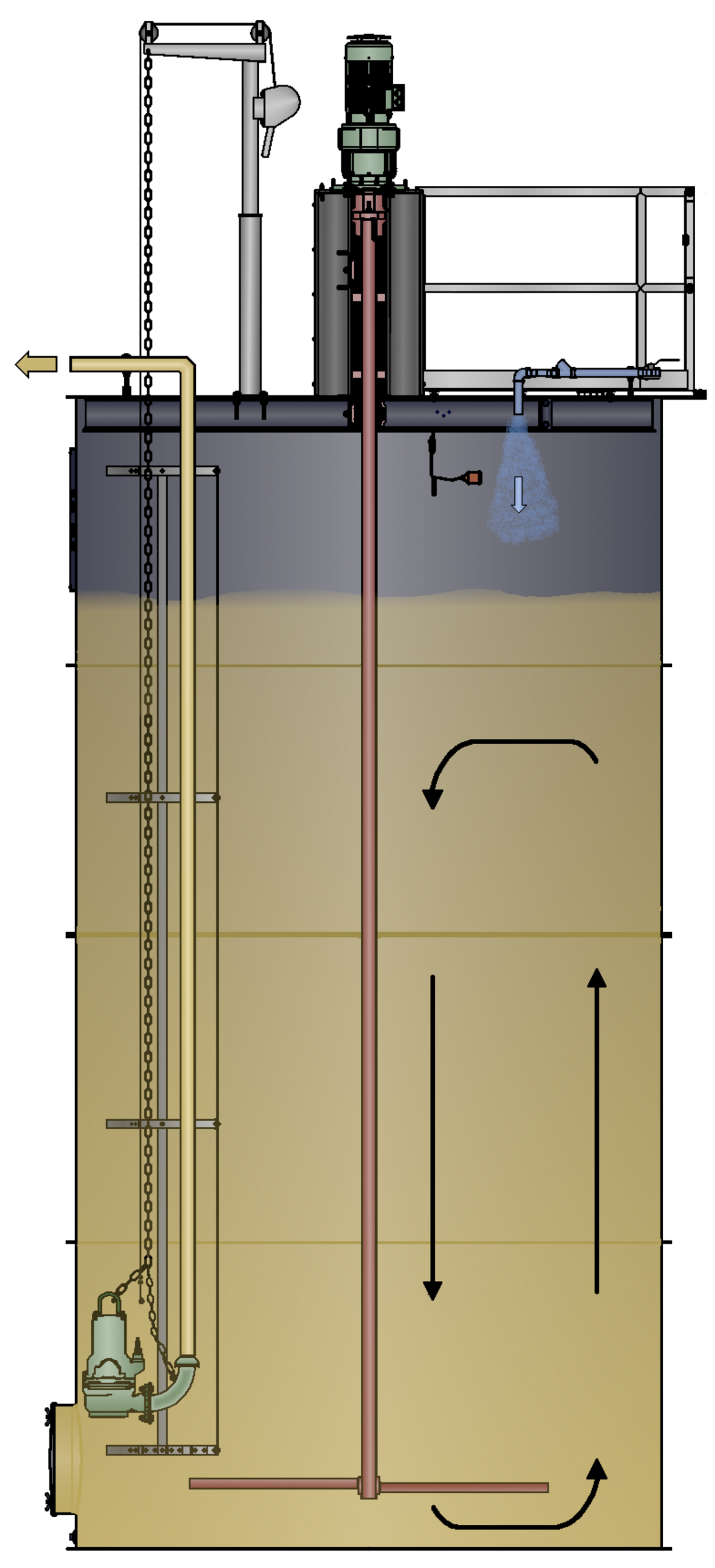

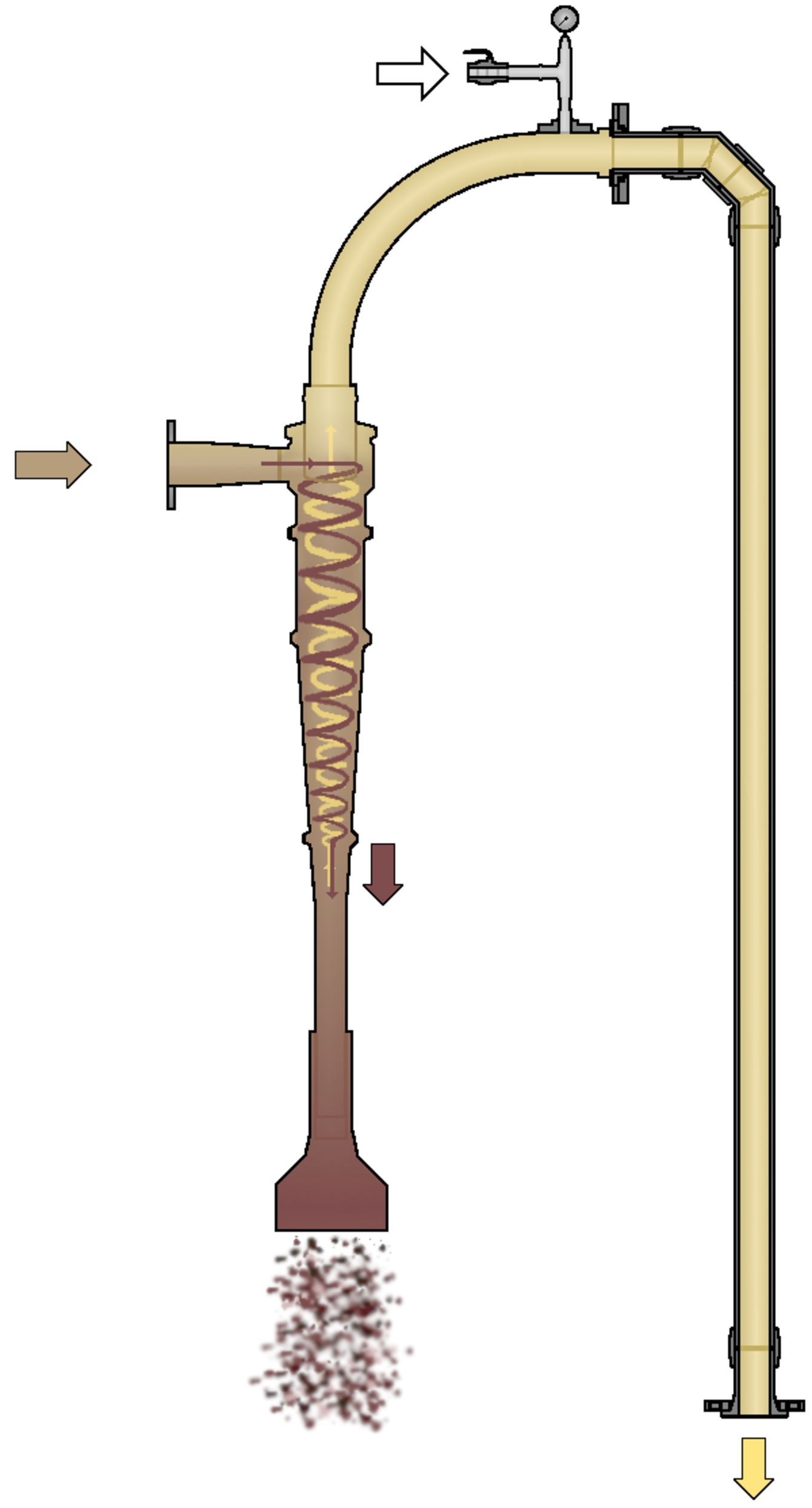

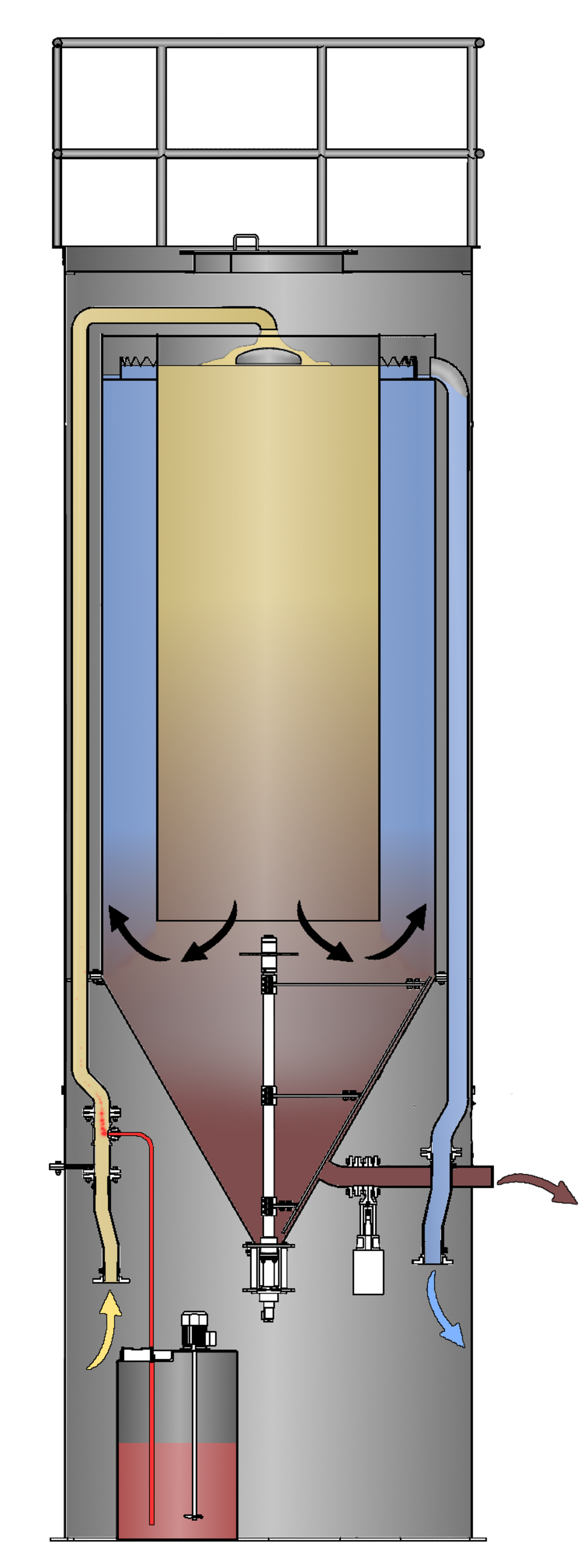

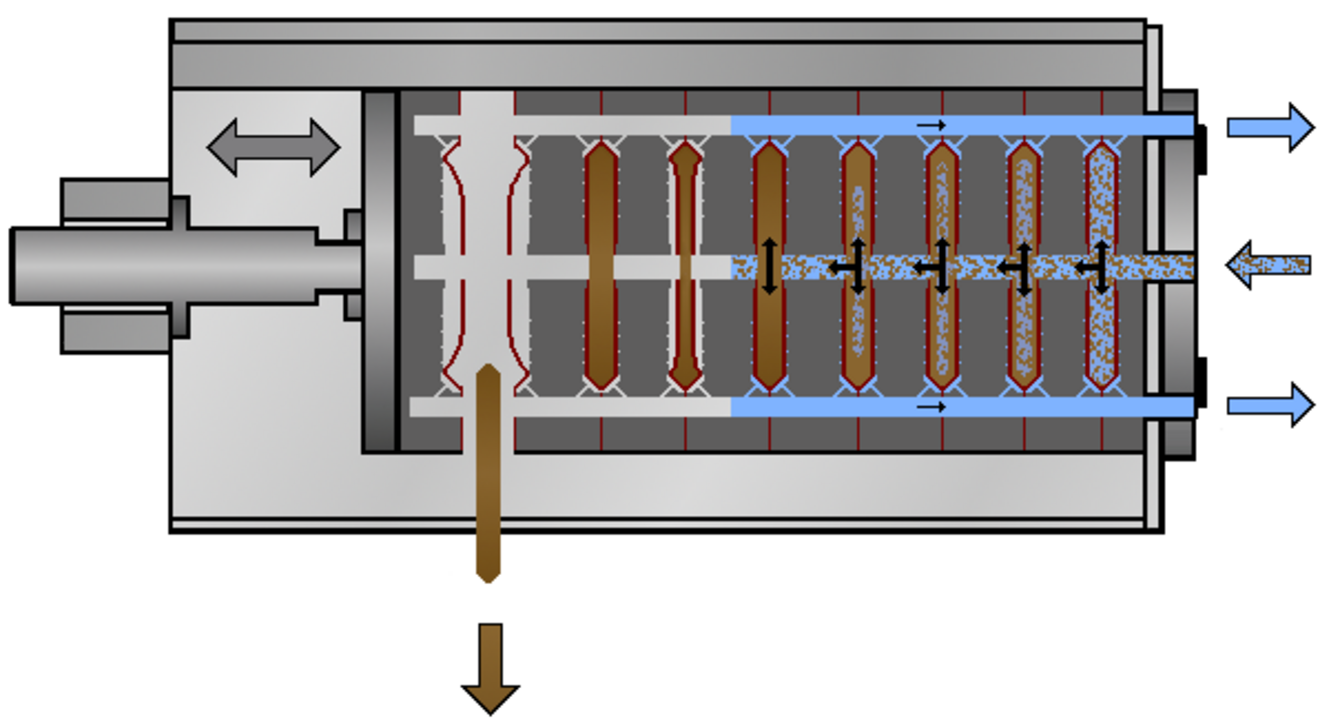

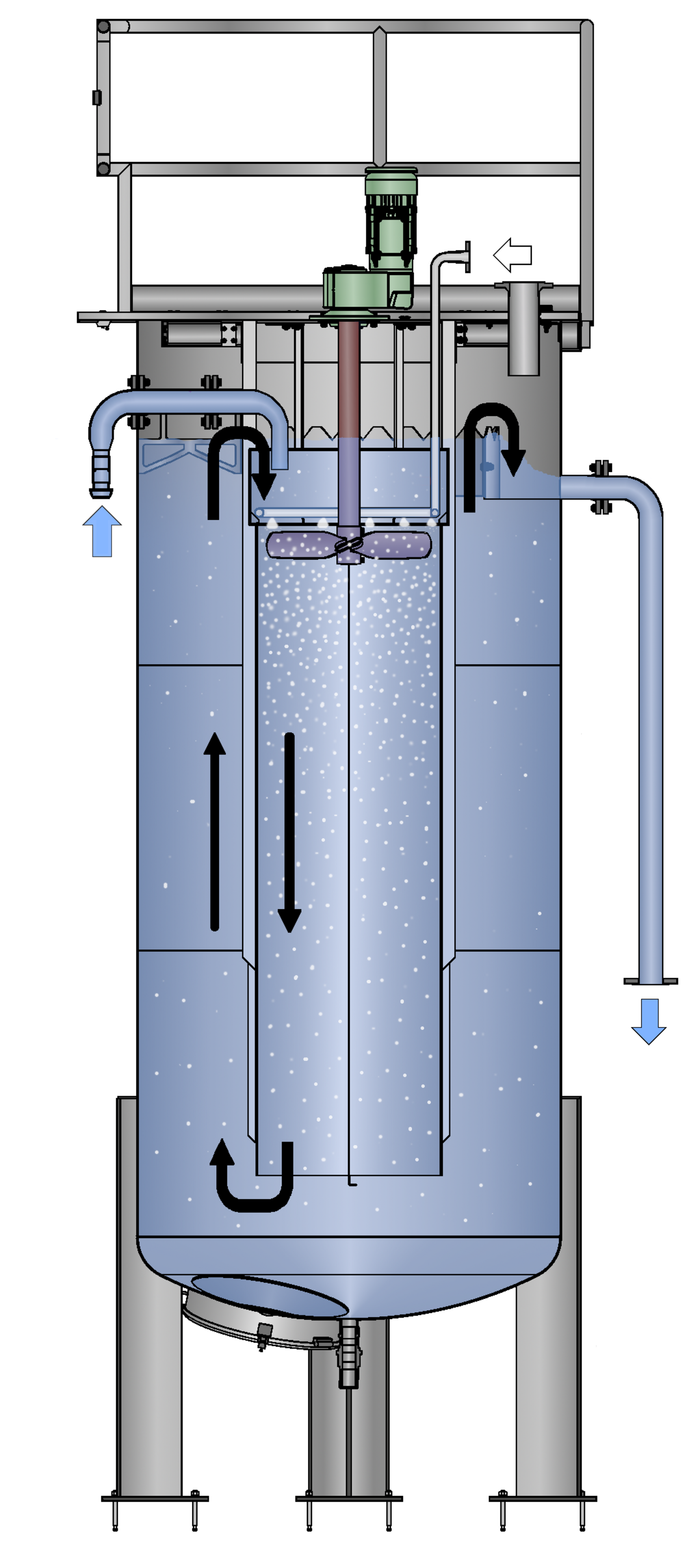

Many concrete and stone processing facilities constantly generate excess and waste quantities of concrete as well as rinsing water containing solid matter and active cement content. The waste process water can be recirculated in order to minimise costs for fresh water and waste water disposal. The solid matter contained in this water can be easily recovered and returned to the material flow if the water is immediately treated.

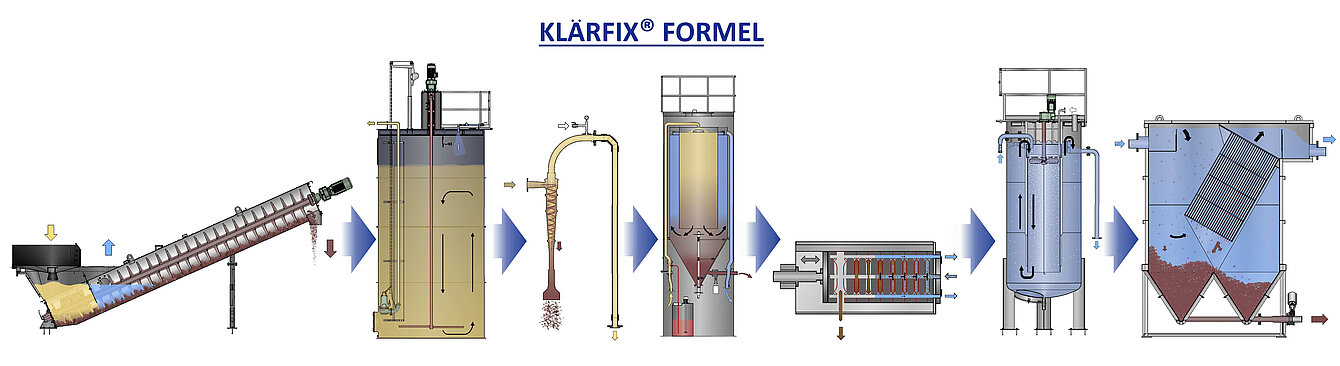

Process water recycling systems from hoelschertechnic-gorator® are built using components that are manufactured in-house and clean the waste water produced based upon the type of contamination and desired form of reuse. You determine the quality of water you need and we use our module system and the KLÄRFIX® formula to determine the technology required!

Use our KLÄRFIX® formula to solve your process water problems!

CONTACTS

Technical Sales

Peter Koch

+49 (0) 2542 916 123

Peter.Koch@hoelschertechnic.de

Technical Sales

Thomas Keller

+49 (0) 2542 916 125

Thomas.Keller@hoelschertechnic.de

Technical Sales

Marvin Pollmann

+49 (0) 2542 916 157

Marvin.Pollmann@hoelschertechnic.de

Contact information for our global representatives can be found here

Advantages that will convince you

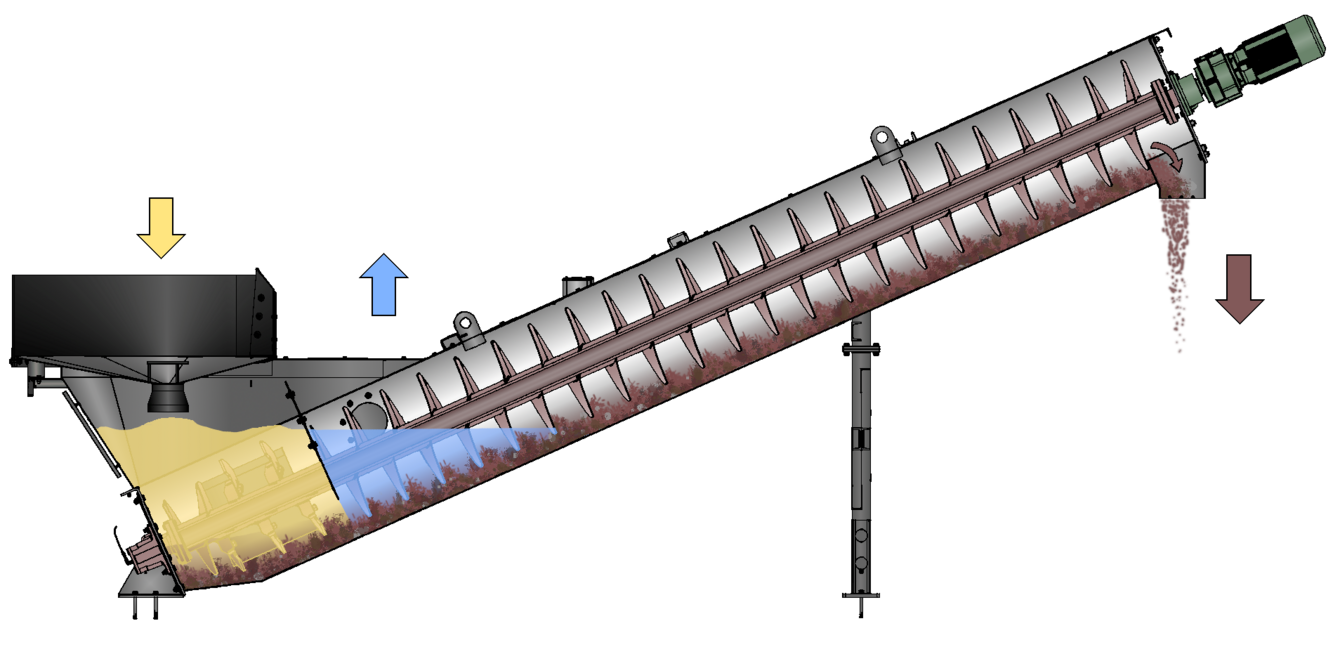

- Complete recycling with 100% reuse of a water and sand/gravel

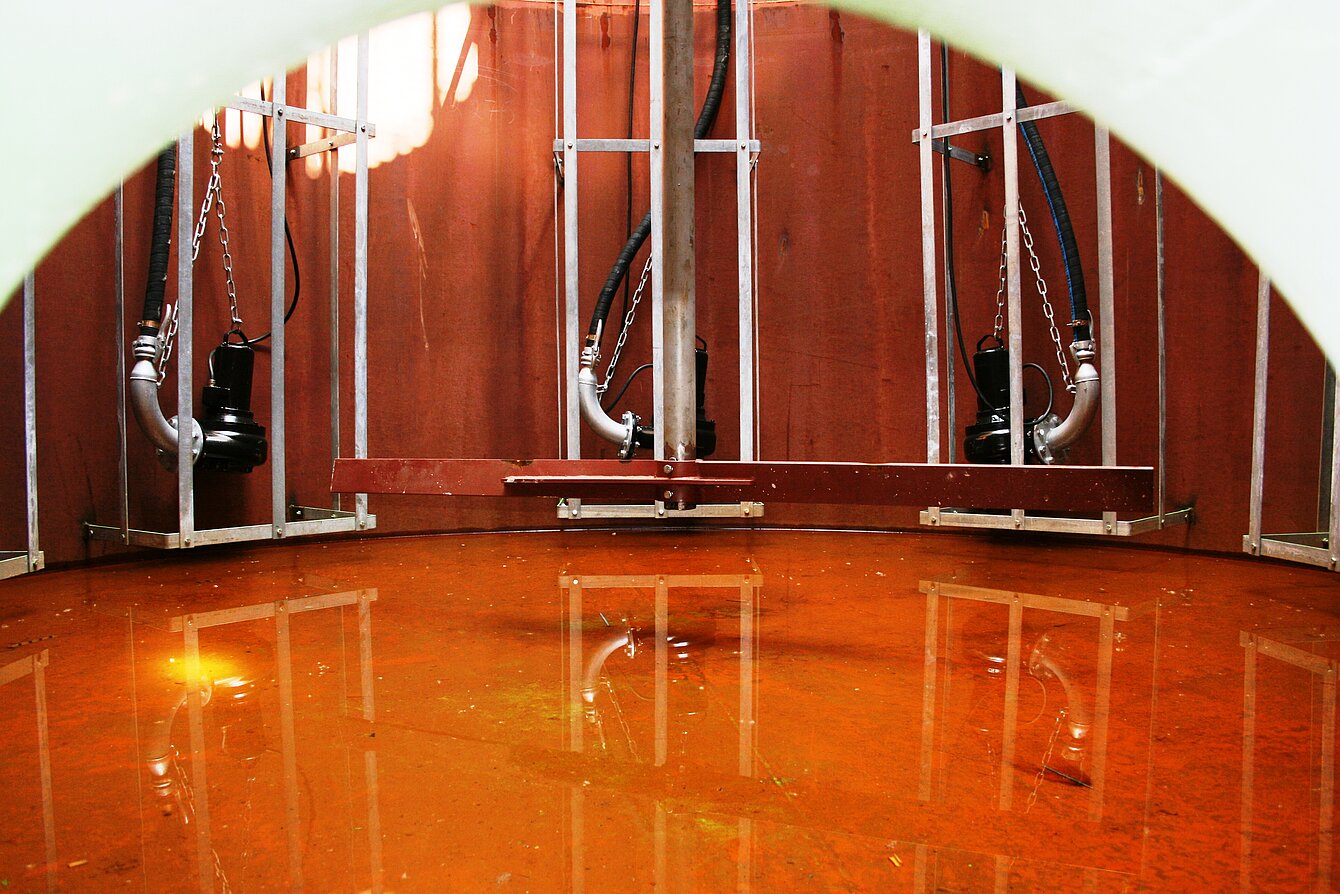

- Proven technology guarantees a high level of operational reliability and availability

- A range of setup variations possible

- High washout capacity with secure cut-off size

- Heavy design for robust, low wear and long-lasting operation

- Extensive modular system

- Bespoke solutions based on customer requirements

Applications

- Ready-mixed concrete production

- Precast concrete element production

- Concrete and paving stone production

- Concrete wall construction systems

- Stone processing