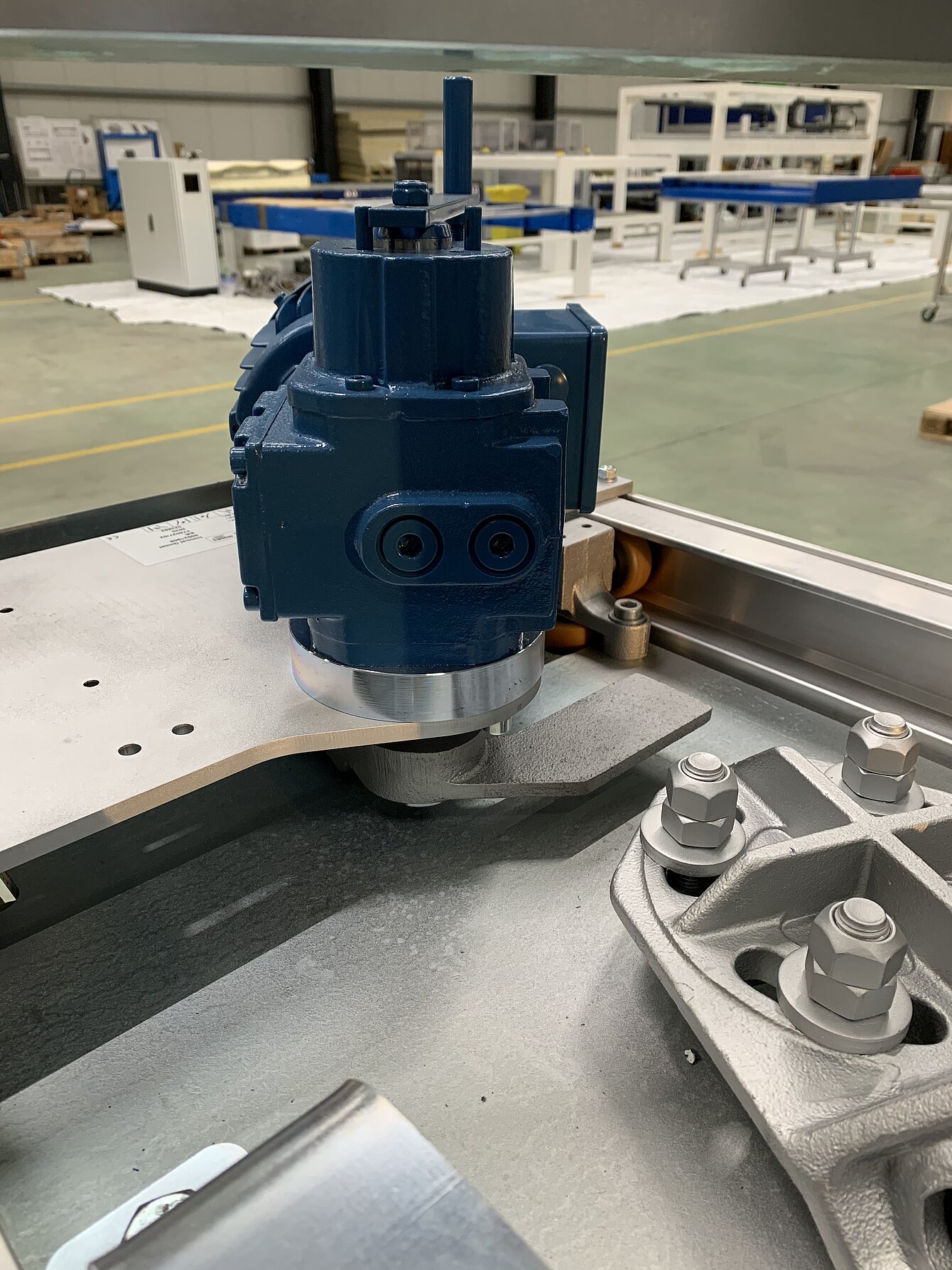

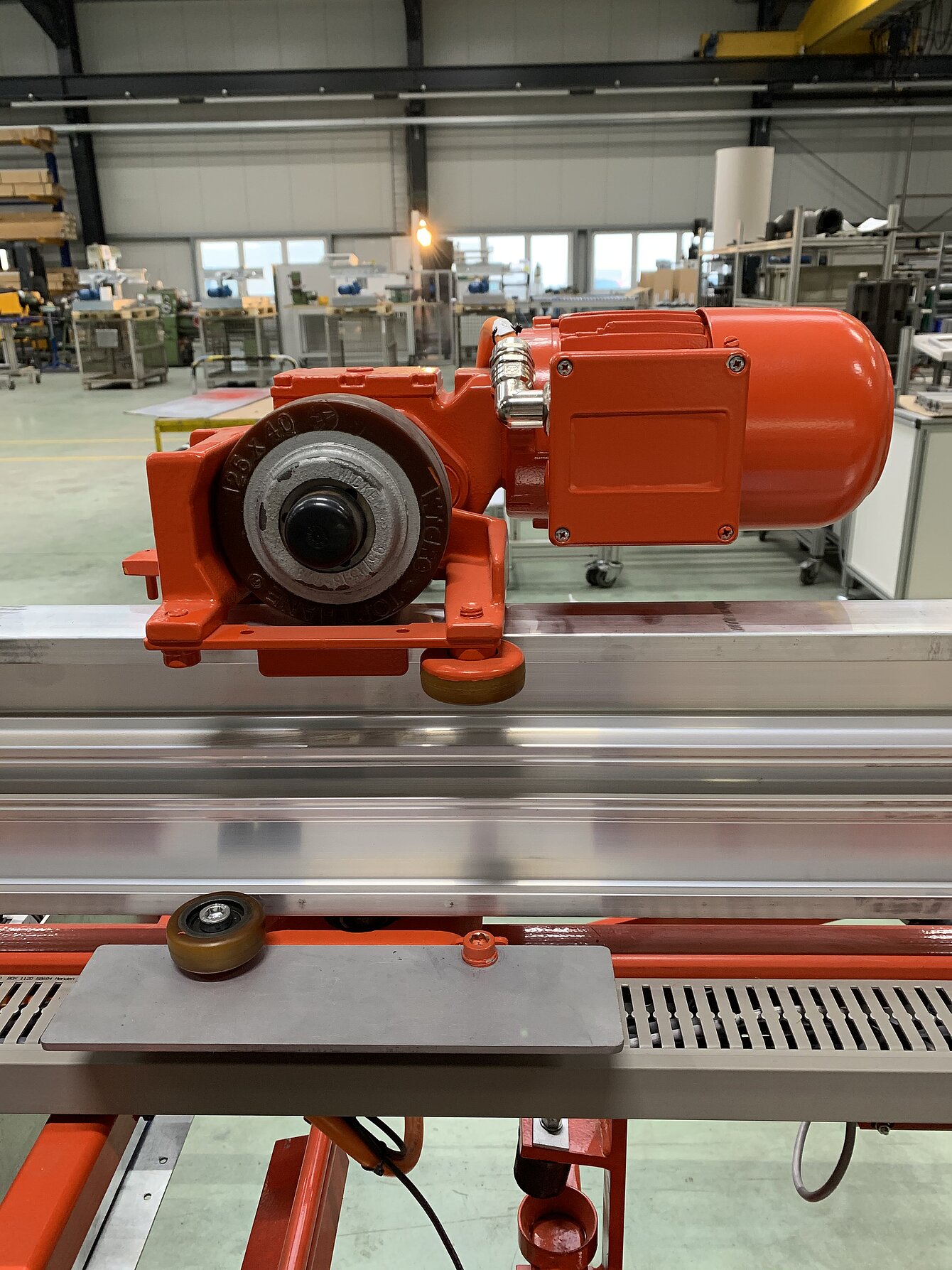

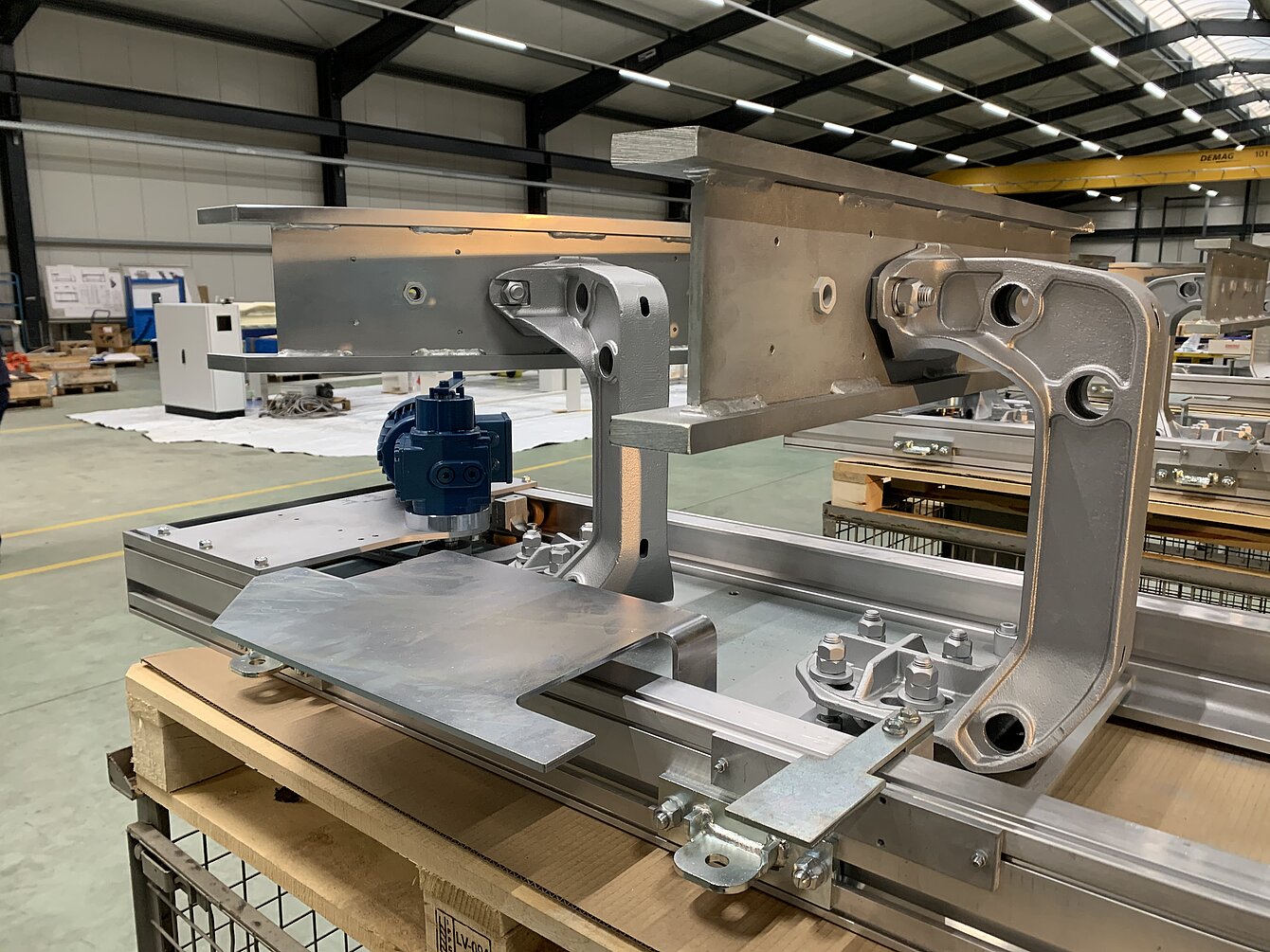

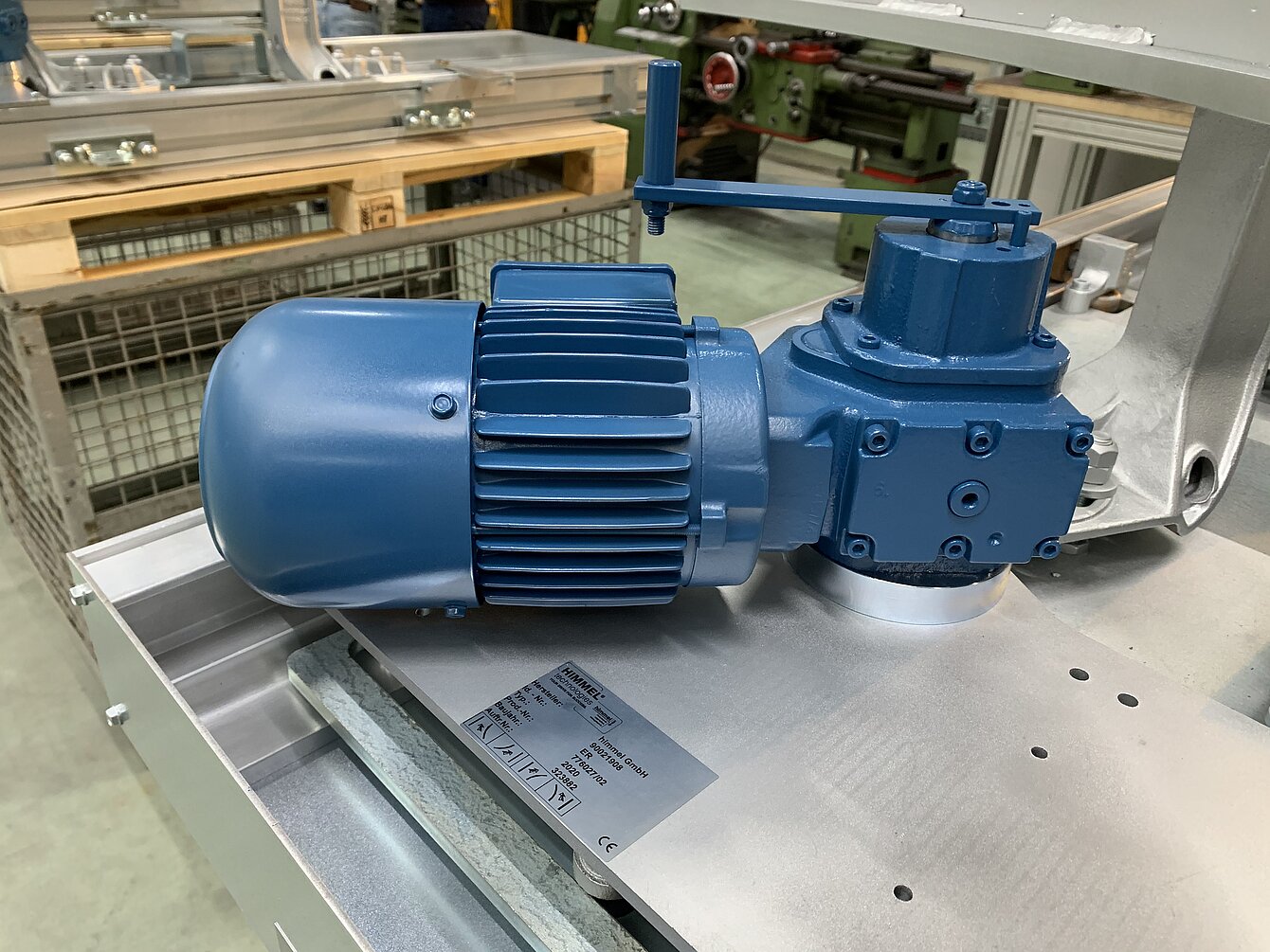

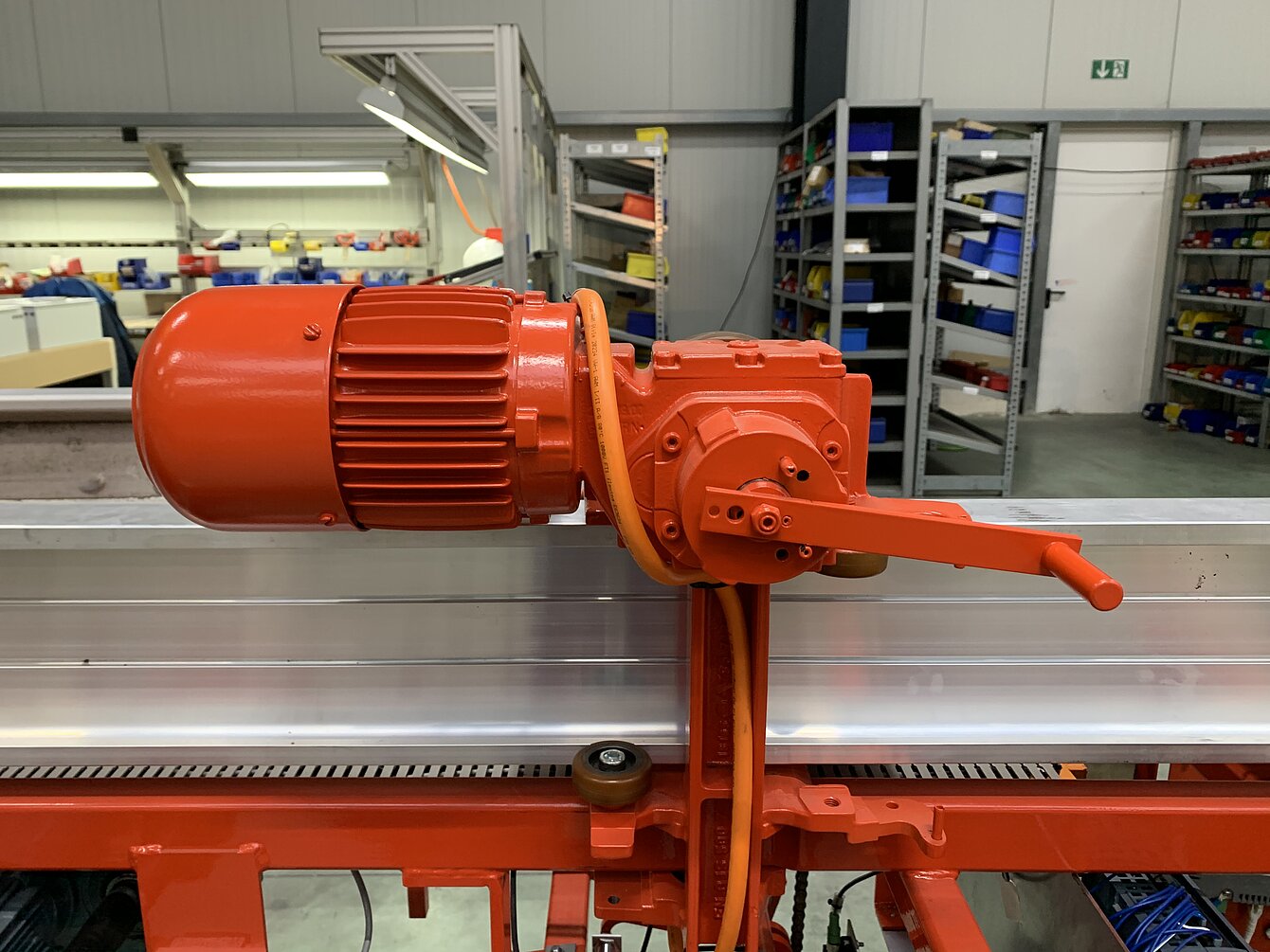

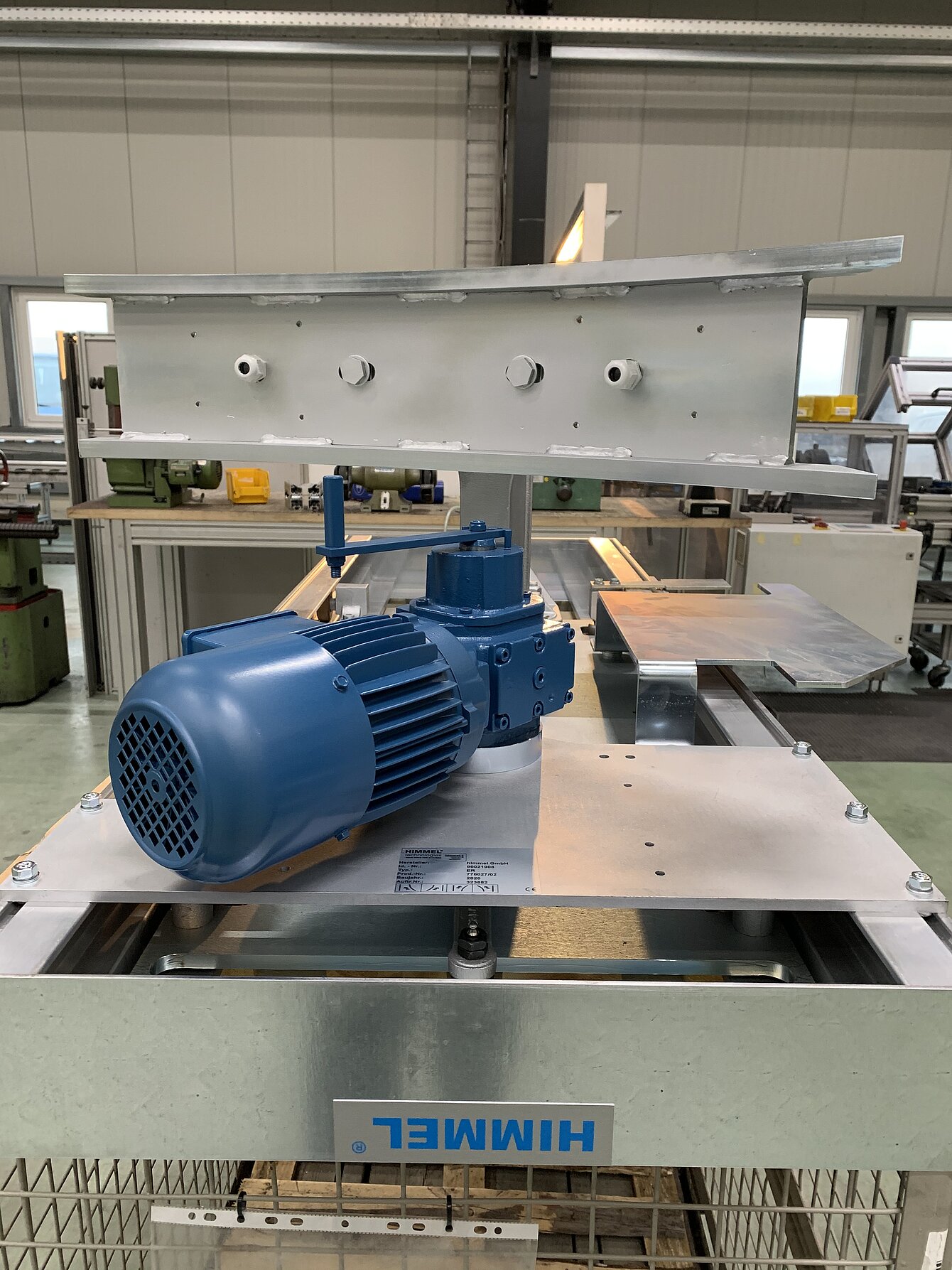

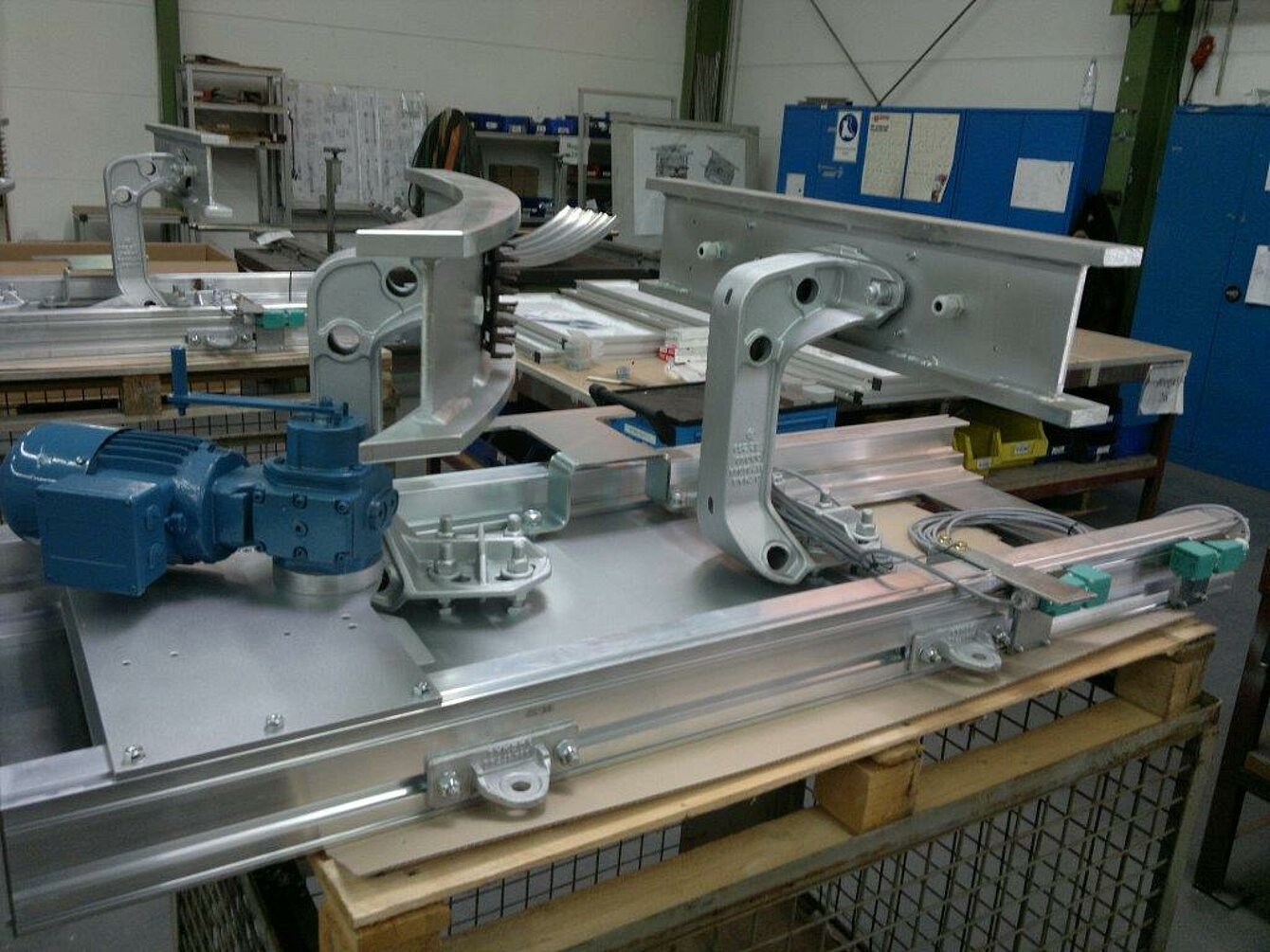

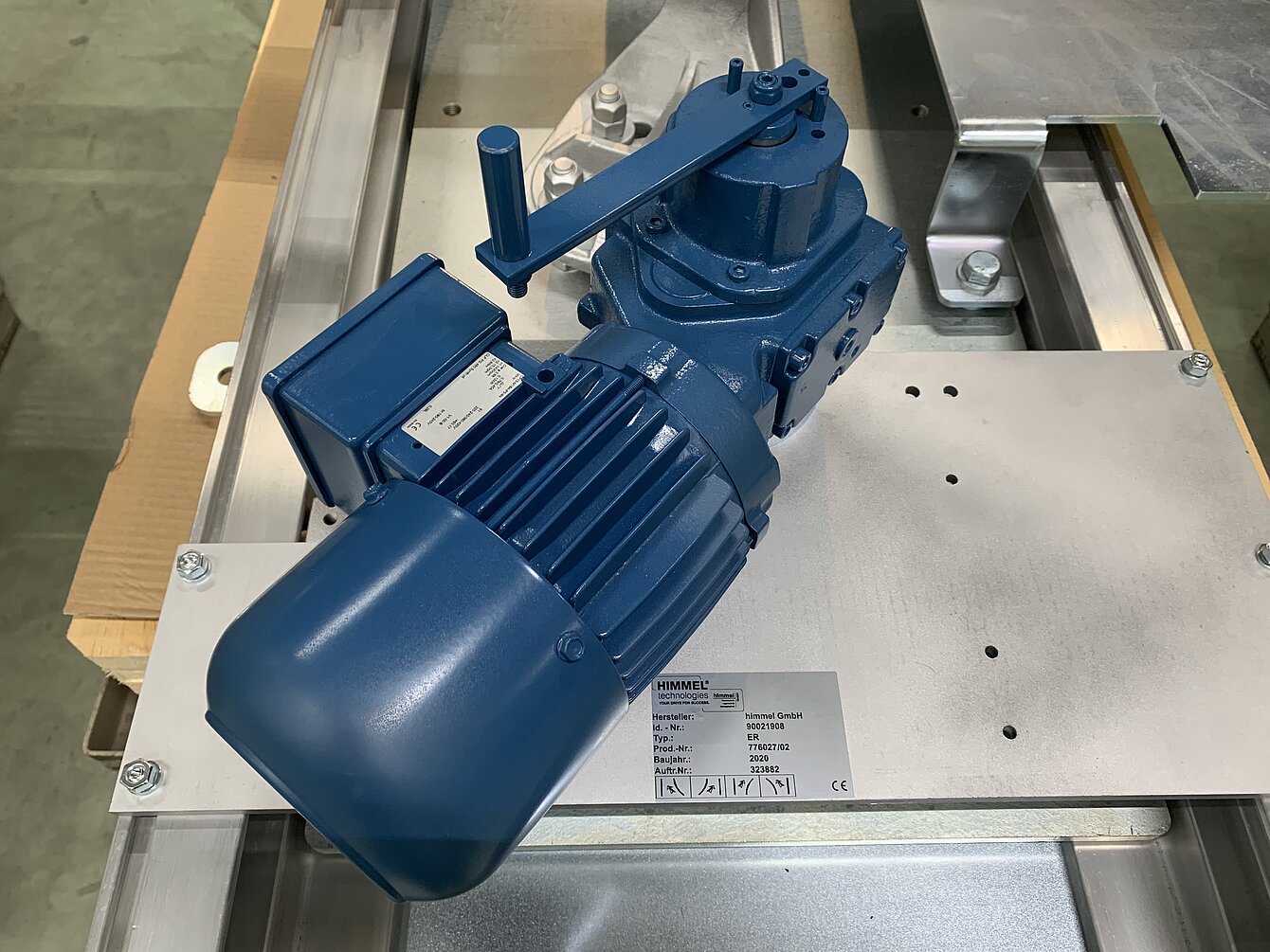

Monorail conveyor drive motors

HIMMEL®Monorail conveyor drive motors (EHB) are suitable both for transporting heavy loads, such as those in the automotive industry during preparatory and final assembly of complete vehicles, and smaller loads such as domestic appliances.

For transporting your projects to the production area, warehouse or for installation, we are certain to have the right gear motor for your needs - our innovative solution for your transport needs.

Cast iron housing for stable and low-vibration continuous operating. Oil loss and ingress of dust is prevented by radial shaft sealing rings with a dust gutter.

The gears of the spur gear stage are milled with a hardened surface finish. Helical gearing and polished tooth flanks for exceptionally low noise operation

Our modular system for gear units provides 6 different gear sizes so that you can always select a suitable drive for your needs and enjoy the associated cost savings. Optionally available are HIMMEL®EHB bevel helical gear motors and HIMMEL®EHB worm helical gear motors.

High torques and high permitted wheel loads characterise our range of monorail conveyor gears. As well as gears that conform to VDI standard 3643, the range also includes heavy load monorail conveyor gear units.

CONTACTS

Commercial Sales

Jana Beckmann

+49 (0) 2542 910 235

Jana.Beckmann@himmelinfo.de

Commercial Sales

Marco Ostendarp

+49 (0) 2542 910 382

Marco.Ostendarp@himmelinfo.de

Technical Sales

Christoph Kloster

+49 (0) 2542 910 253

Christoph.Kloster@himmelinfo.de

Technical Sales

Christian Mesken

+49 (0) 2542 910 259

Christian.Mesken@himmelinfo.de

Technical Sales

Tobias Middendorf

+49 (0) 2542 910 134

Tobias.Middendorf@himmelinfo.de

Technical Sales

Ulrich Schwitte

+49 (0) 2542 910 322

Ulrich.Schwitte@himmelinfo.de

Advantages

- High availability and fast delivery of important spare parts

- Emergency service

- Onsite repairs

- Specialist staff

- Servicing and repairs for all manufacturers

- High degree of vertical integration

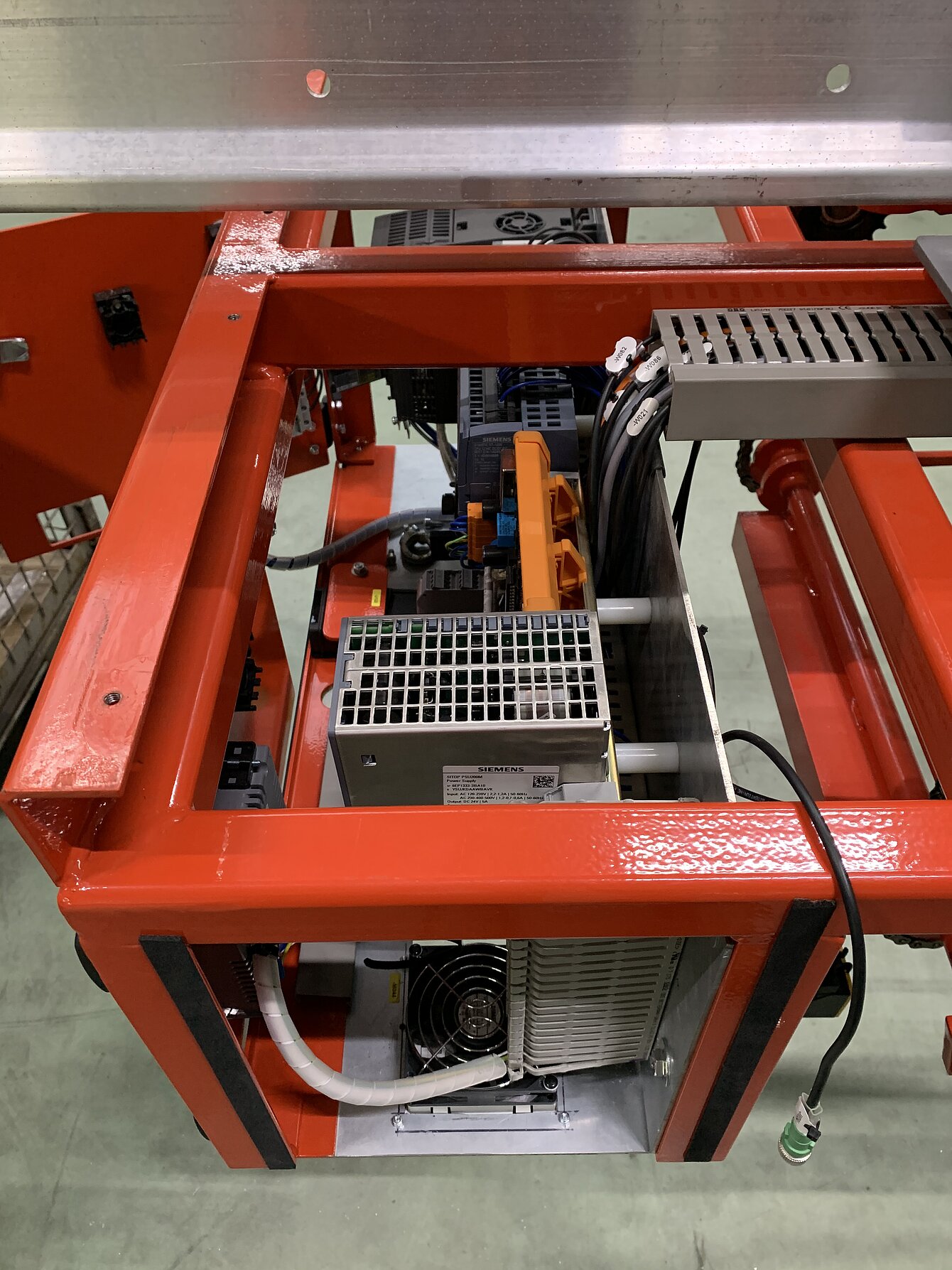

- Control systems are built inhouse

- Bespoke solutions

- Safe and easy to use in work areas

- Flexible routing - adaptable to any alignment

- Also suitable for heavy weights, high and flexible transport speeds

- Reuse of transmissions in plant renovations, adaptations and enhancements

- Low maintenance costs

- Simple installation of additional carriages

- Clutch for disconnecting power transfer between drive and conveyor system

Applications

- Automotive industry

- Chemical industry

- Food technology (hygiene requirements)

- Beverages industry

- Packaging machines

- Warehouse and logistics

- Leisure facilities

- Domestic appliance industry

Features and technical data

Features

- 6 sizes

- Range of torques and gear ratios from the modular range of HIMMEL gear motors

- Helical gearing

- Polished tooth flanks for quiet running

- Clutch for disconnecting power transfer between drive and conveyor system

- Cast iron housing for stable and low-vibration continuous operation

- Performance can be adapted for any application

Options

- Brake assembly

- Shaft design according to your specifications

- Design with two motor speeds (2/4; 4/8; 8/2; 12/2 pin)

- Frequency converter operation

- Motor mounting via coupling adapter

Further options available based on customer requirements.

Technical data CF15

Type CF15

Torque: 40 Nm

Total load: 700 kg

Axle load: 3,500 N

Technical data CF25

Type CF25

Torque: 130 Nm

Total load: 1,200 kg

Axle load: 9,000 N

Technical data KF34

Type KF34

Torque: 200 Nm

Total load: 1,500 kg

Axle load: 7,500 N

Technical data KF45

Type KF45

Torque: 330 Nm

Total load: 2,000 kg

Axle load: 11,500 N

Technical data KF65

Type KF65

Torque: 500 Nm

Total load: 4,000 kg

Axle load: 20,000 N

Technical data KF85

Type KF85

Torque: 900 Nm

Total load: 5,000 kg

Axle load: 25,000 N