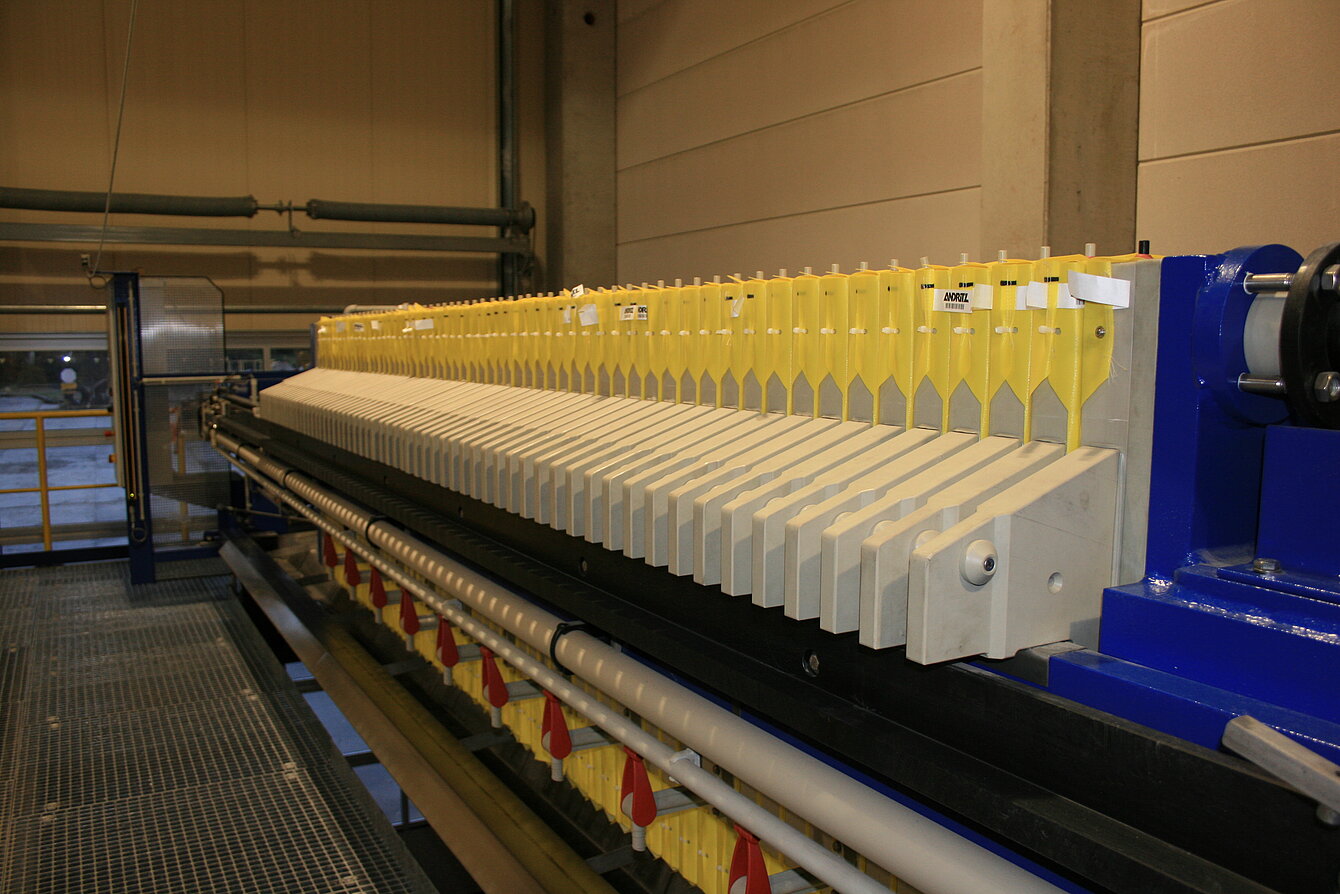

Waste water treatment

hoelschertechnic-gorator® GmbH & Co. KG plans, delivers and assembles all equipment for municipal and industrial waste water treatment plants.

We provide complete treatment plants in close collaboration with planning agencies, sewage boards, municipalities and industry. Existing plants can be modernised or expanded. We use system components that we have made ourselves and work together with competent partners to deliver effective and economical waste water solutions.

Alongside product quality, preventative servicing is a prerequisite for long-lasting, disruption-free operation. Regular maintenance intervals are also essential. And if the worst comes to the worst, any damaged parts can be replaced. These are all jobs that our service staff will take care of.

CONTACTS

Technical Sales

Peter Koch

+49 (0) 2542 916 123

Peter.Koch@himmelinfo.de

Technical Sales

Thomas Keller

+49 (0) 2542 916 125

Thomas.Keller@himmelinfo.de

Technical Sales

Simon Richels

+49 (0) 2542 916 139

Simon.Richels@himmelinfo.de

Contact information for our global representatives can be found here

Advantages

- Everything you need in one place

- Competent partner for new deliveries, maintenance and conversions

- Full service including planning, production, assembly and customer service

- Bespoke solutions based on customer requirements

Applications

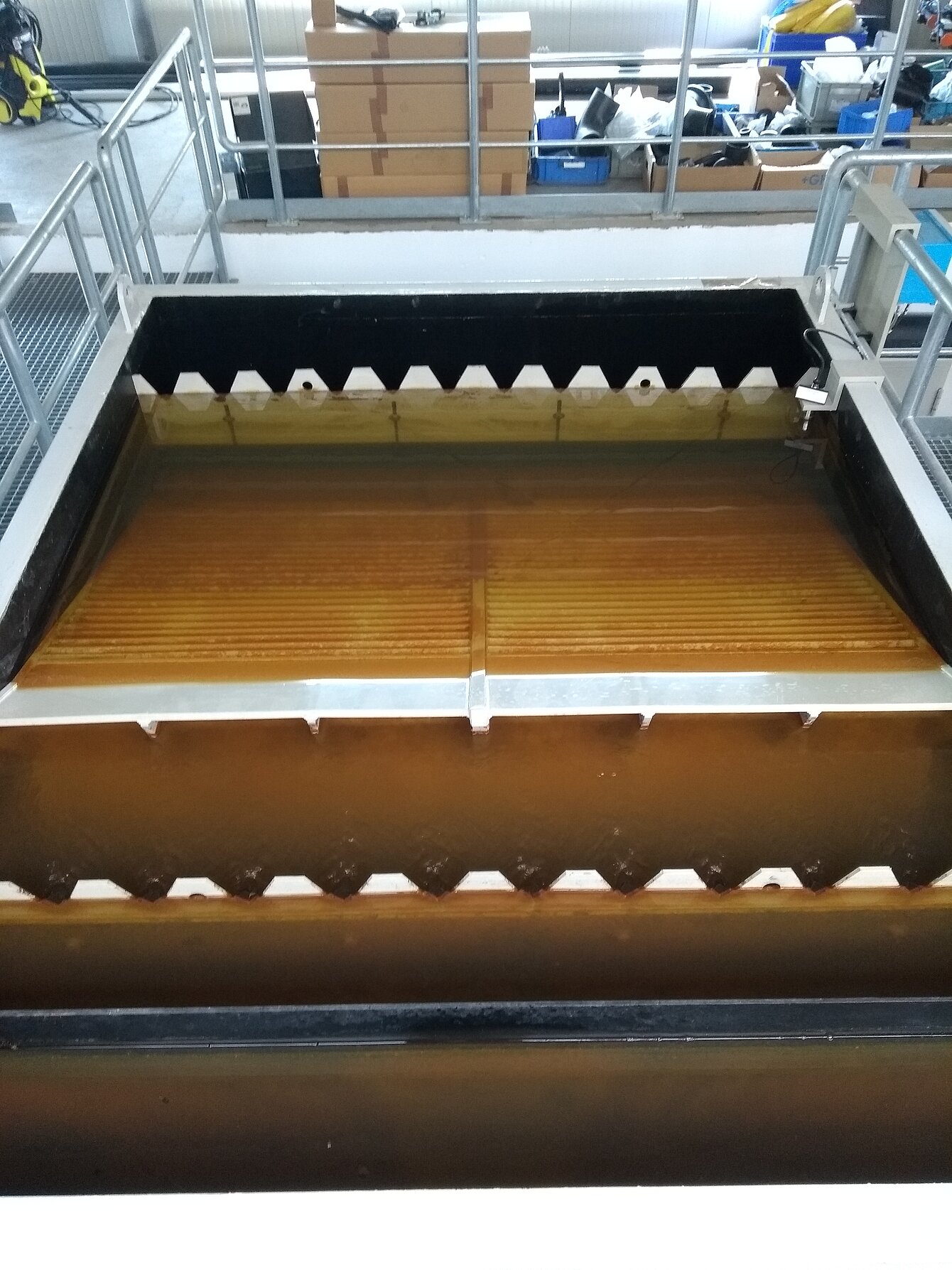

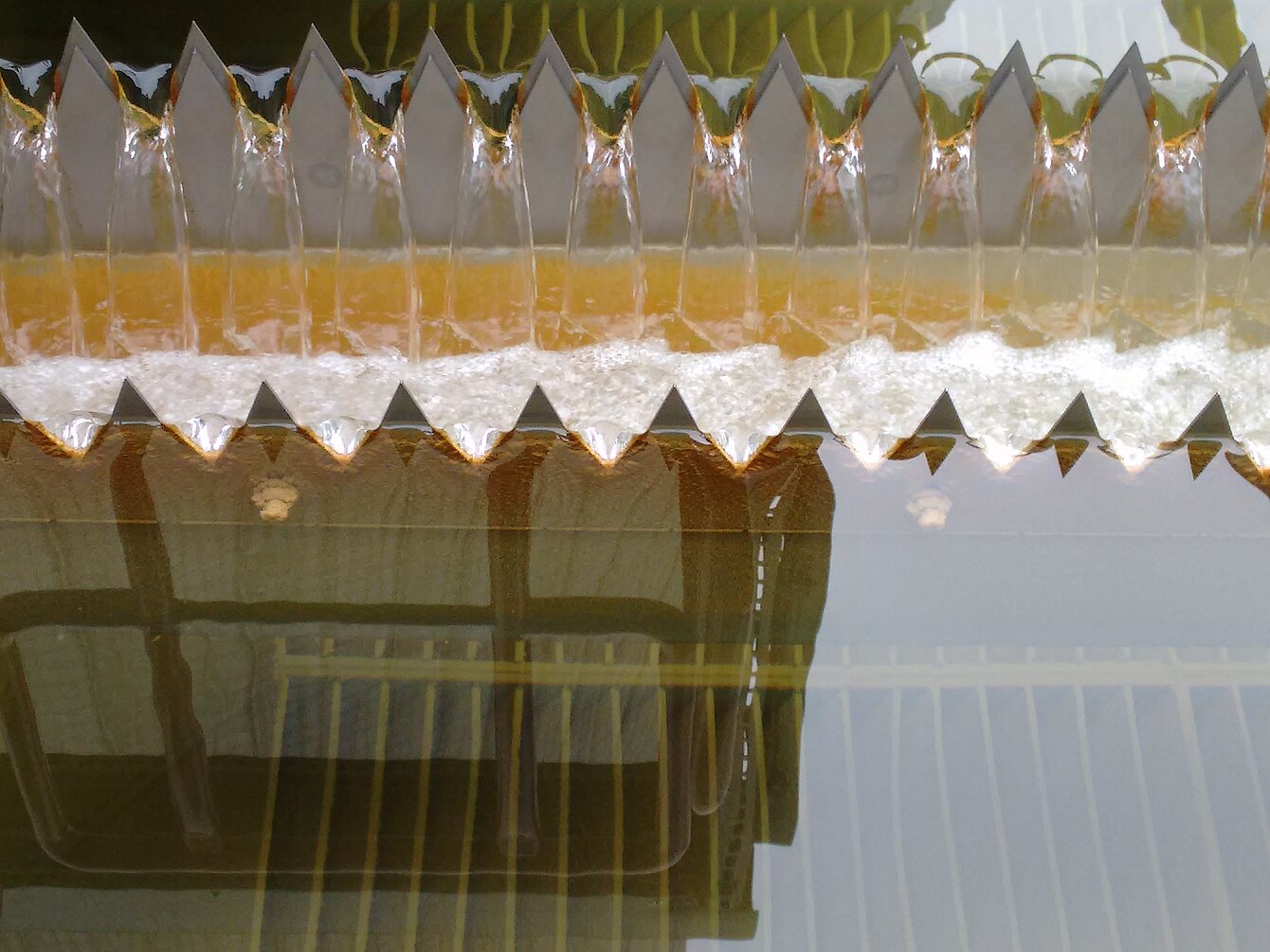

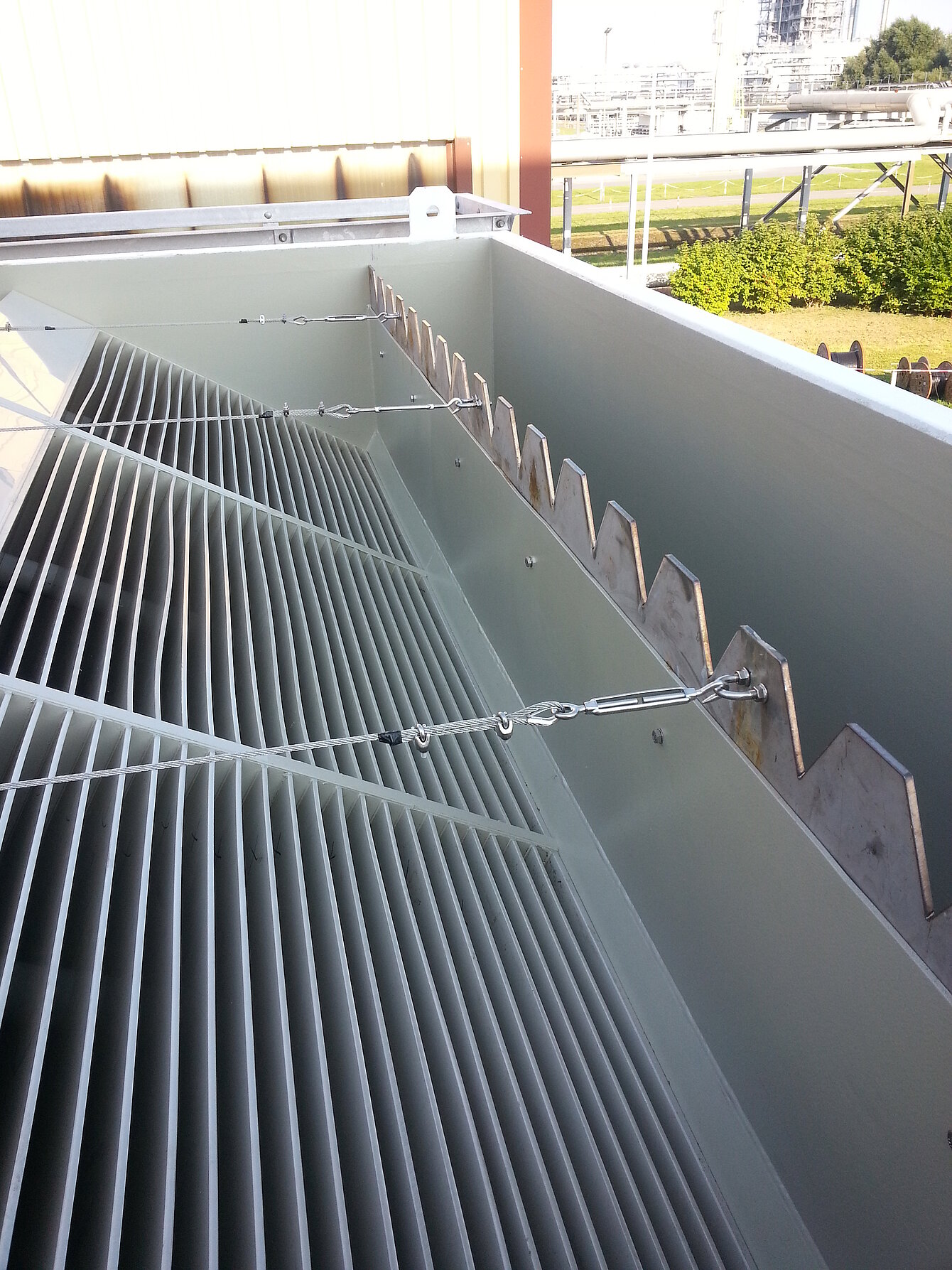

- Municipal waste water treatment plants

- Industrial waste water treatment plants

- Rainwater storage

- Pumping stations

- Steel mills

- Metalworking companies

- Power stations

- Chemical parks

- Refuse incineration plants

- Refineries

- Food factories