Screening technology

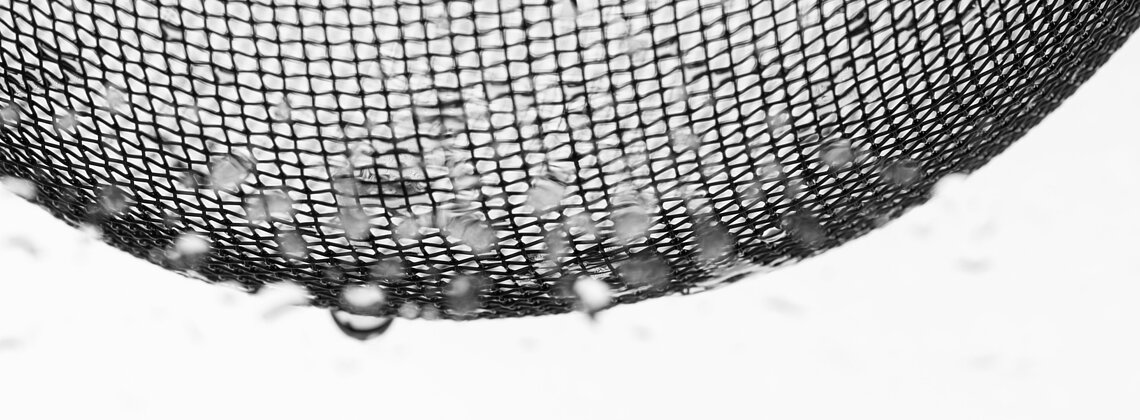

Screens made by hoelschertechnic-gorator® use the principal of gravity filtration for the mechanical separation of solids and liquids.

This technology filters a two-phase mix of materials into a “liquid phase” and into a “solid phase” and thus divides a flow of material into two separate flows for subsequent processing.

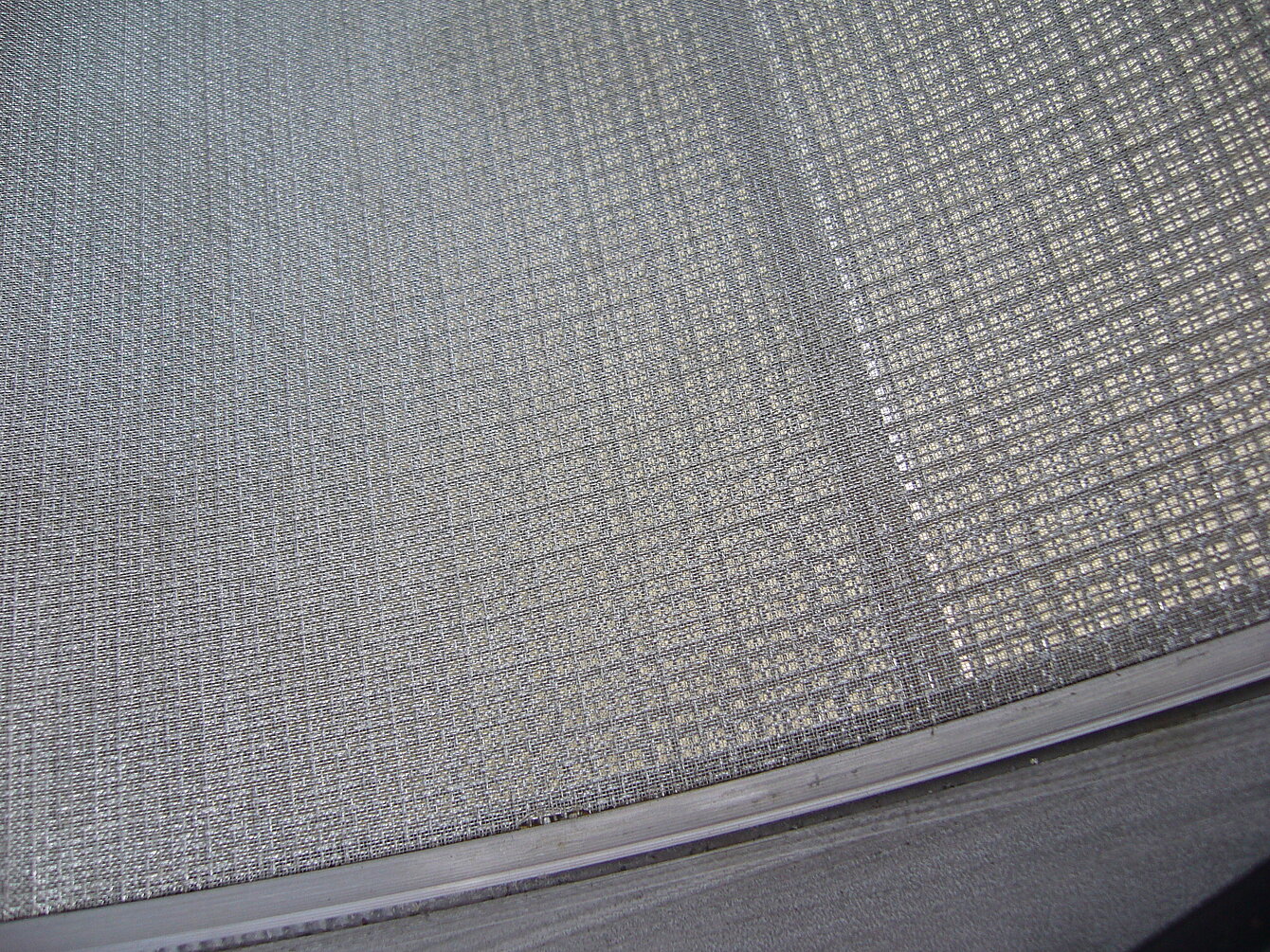

hoelschertechnic-gorator® supplies screens for a wide range of applications with a range of different options for liquid phase inlet and discharge of solid matter as well as the desired mesh size.

hoelschertechnic-gorator® offers tailored solutions for customers made in its own factory with various different screens that can be put together using a modular system for standard or special designs. Our screens are suitable for many different applications in industrial and municipal water and sewage treatment.

CONTACTS

Technical Sales

Jens van de Maat

+49 (0) 2542 916 160

Jens.vandeMaat@himmelinfo.de

Technical Sales

Oliver Severing

+49 (0) 2542 916 115

Oliver.Severing@himmelinfo.de

Contact information for our global representatives can be found here

Advantages

- Sizes based on mesh fineness and required throughput

- Screen drums and plates interchangeable as needed

- Designs adapted to customer requirements for product inflow, outflow and sediment discharge

- Standard material 1.4301, optionally using 1.4404 or 1.4571

- Electropolished components available

- Speed regulation using frequency converter and electrical cabinet possible

- High pressure and standard screen cleaning systems available

- External, internal or combination screen cleaning

Applications

- Municipal sewage

- Industrial sewage

- Rainwater management

- Preserved products production

- Fruit processing

- Meat processing

- Food industry

- Slaughterhouses

- Agriculture

- Potato processing

- Milk dairies

- Cheese dairies

- Textile industry

- Tanneries

- Paper industry

- Pharmaceutical industry

- Chemical industry

- Petrochemical industry

- Biogas plants

Features and technical data

HTMS DRUM SHEAR SCREEN

| HTMS DRUM MESH SHEAR SCREEN

|

DRUM SCREEN

| HDFS ROTATING FINE SCREEN

|

HSS STATIC SCREEN

|